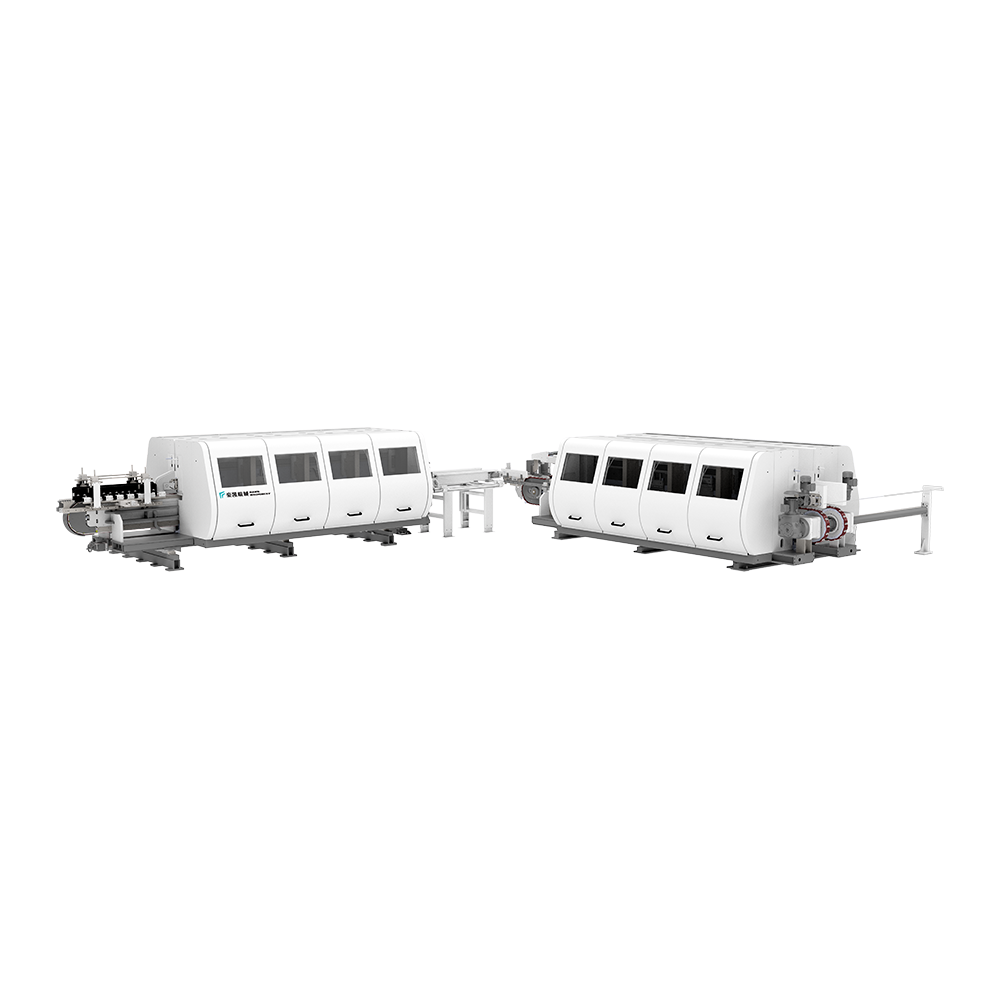

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsIn the world of woodworking machinery, the tenoner machine is a core piece of equipment used to produce high-precision tenons. It processes the ends of wooden pieces into smooth, accurate tenons to create strong joints for furniture, doors, windows, and other products. Based on their structure and function, tenoner machines are primarily divided into two types: Single End Tenoner Machines and Double End Tenoner Machines. These two types of equipment differ significantly in production efficiency, processing accuracy, and application scope.

A Single End Tenoner Machine, as the name suggests, can only process one end of a wooden piece at a time. Its workflow is relatively simple: the operator clamps the wood onto the workbench, and the machine's saw blades and cutters successively process one end of the wood to create the tenon. If the other end needs to be processed, the wood must be manually flipped and processed again.

Advantages:

Low Cost: The simple structure and manufacturing process result in a lower price point.

Small Footprint: The compact size is suitable for small workshops or factories with limited space.

Flexible Operation: It is more flexible for small-batch, non-standardized production or situations that require frequent changes in processing dimensions.

Disadvantages:

Low Production Efficiency: Processing only one end at a time requires manual flipping and repositioning, which significantly slows down production.

Limited Processing Accuracy: Due to the need for two manual clamping operations, it's difficult to ensure perfect symmetry and dimensional consistency between the two tenons, leading to potential errors.

The Double End Tenoner Machine, also known as a Double Sided Tenoner or Double-End Sizing and Tenoning Machine, is a highly efficient piece of equipment that can process both ends of a wooden piece simultaneously. Its working principle is as follows: the wood is conveyed by a chain or track feed system, and there's a processing unit on each side, including saw blades and cutters. These units work in sync to cut both ends of the wood.

Advantages:

High Production Efficiency: It completes the processing of both ends in a single pass, making it several times faster than a single end tenoner machine. This is ideal for large-batch, standardized production.

High Processing Accuracy: Since the wood is precisely fixed by the conveying system throughout the entire process and both ends are processed synchronously, it ensures that the tenons' dimensions, angles, and symmetry achieve extremely high precision.

More Powerful Functionality: Modern Double End Tenoner Machines often integrate multiple processing units. In addition to tenoning, they can perform compound operations like grooving, profiling, and edge trimming, enabling a "one pass, multiple processes" production model.

High Degree of Automation: The equipment is usually equipped with automatic feeding and discharging systems, which reduces manual intervention and minimizes labor intensity and human error.

Disadvantages:

High Equipment Cost: The complex structure and high technical content make the initial investment much higher than a single end tenoner machine.

Large Footprint: The equipment is typically large, requiring more factory space.

Complex Setup: Initial setup or changing product specifications requires precise adjustments to the processing units on both sides, which can be a complex process.