Can HAWK Machinery China Co., Ltd.'s WPC Floor V-Groove Painting Machine be Adjusted to Accommodate Grooves of Different Depths?

HAWK Machinery China Co., Ltd., a renowned name in the floor treatment equipment sector, has long been at the forefront of innovative technology and manufacturing excellence. Established in 2005, the company has quickly risen to prominence as a national high-tech enterprise, specializing in the research, development, manufacturing, sales, and service of precision floor treatment equipment. With its steadfast commitment to high standards, HAWK has garnered prestigious honors such as Jiangsu Province Specialized and New Enterprise, Jiangsu Province Enterprise Technology Center, and Jiangsu Province Private Technology Enterprise.

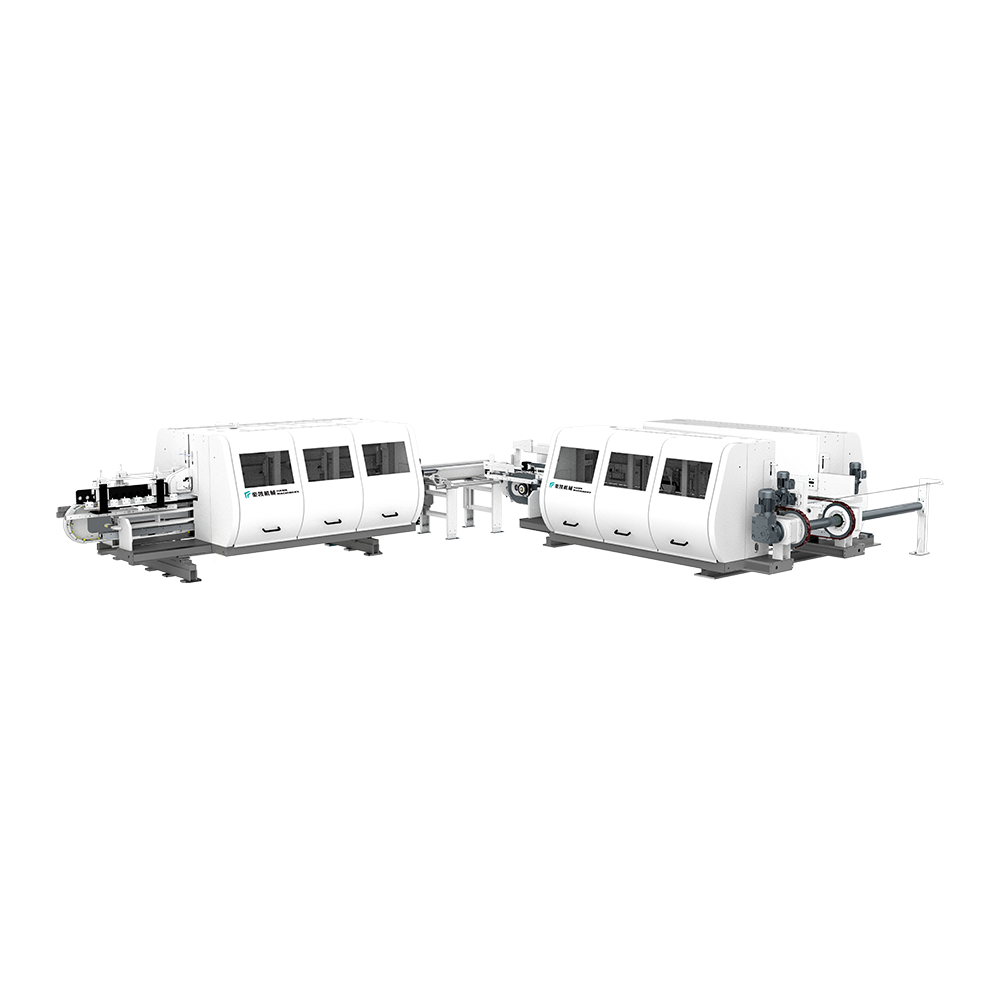

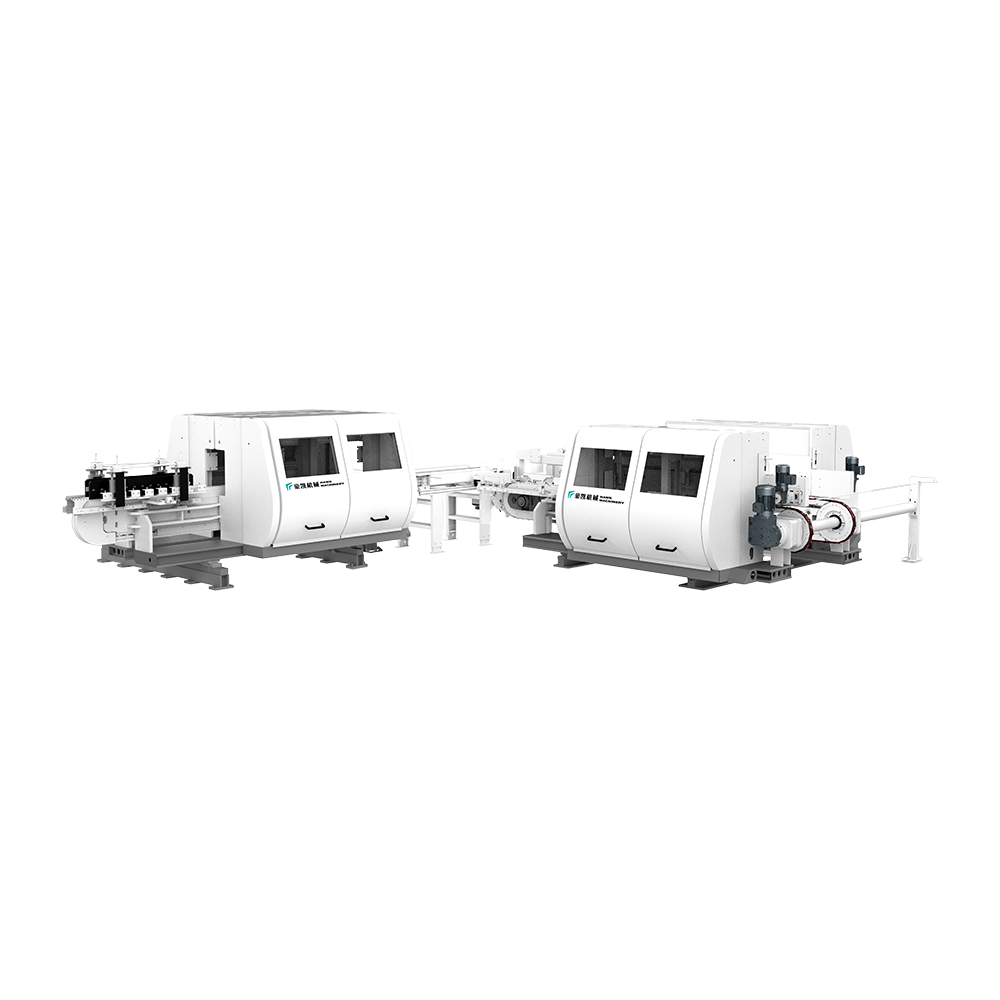

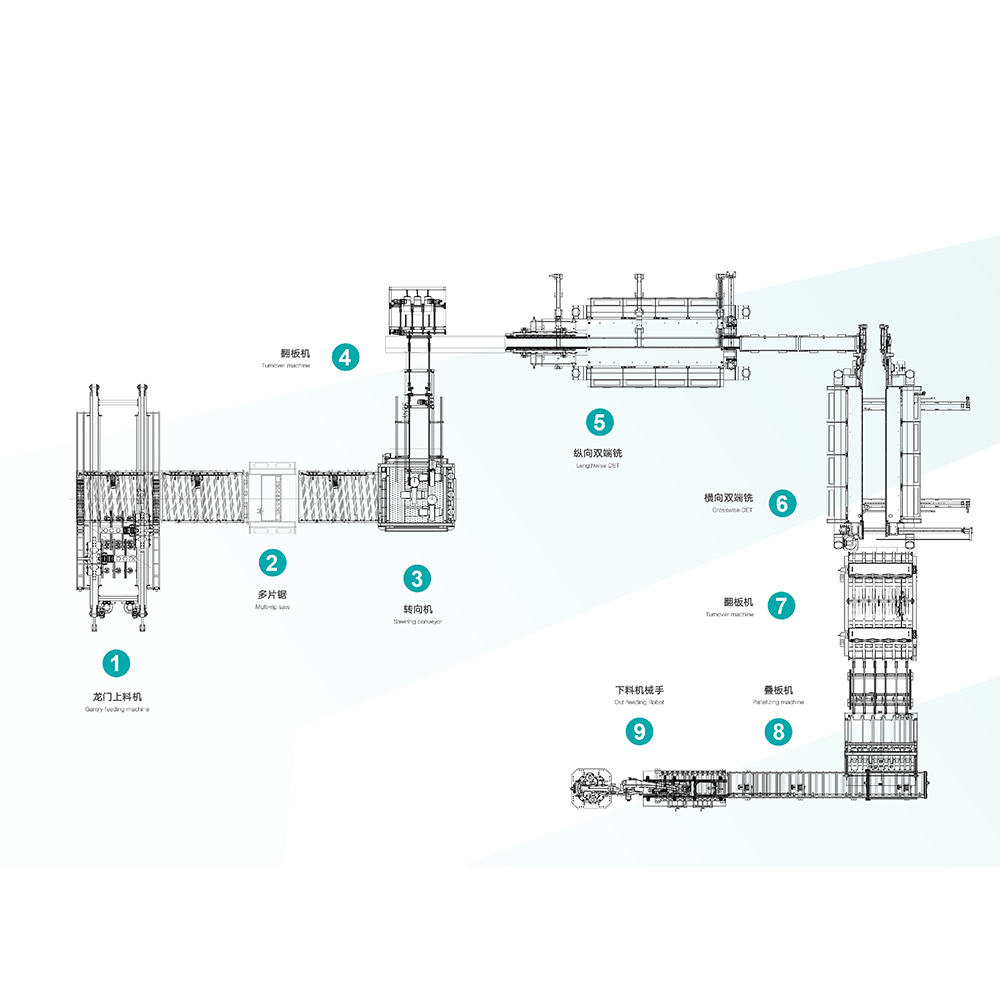

Among their flagship products are the Laminate Floor V-Groove Painting Machine, designed specifically for WPC (Wood-Plastic Composite) and laminate floors. These machines have earned recognition for their exceptional precision, reliability, and ability to deliver superior finish quality. What sets HAWK's offerings apart is not only their cutting-edge technology but also the company's capacity to customize machines to meet the unique demands of various industries. The ability to adjust these machines for specific applications is an integral part of the company's appeal, particularly when it comes to accommodating grooves of different depths.

The question arises: Can the WPC Floor V-Groove Painting Machine be adjusted to accommodate grooves of varying depths?

The answer is a resounding yes. HAWK’s advanced V-Groove Painting Machines are designed with flexibility in mind. Built to meet the diverse needs of the flooring industry, these machines incorporate state-of-the-art features that enable precise control over groove depth. Whether dealing with shallow or deeper grooves, the machines are equipped with adjustable settings that ensure a flawless, uniform coating across a wide range of groove profiles. This adaptability allows manufacturers to achieve the desired finish without compromising on quality or efficiency.

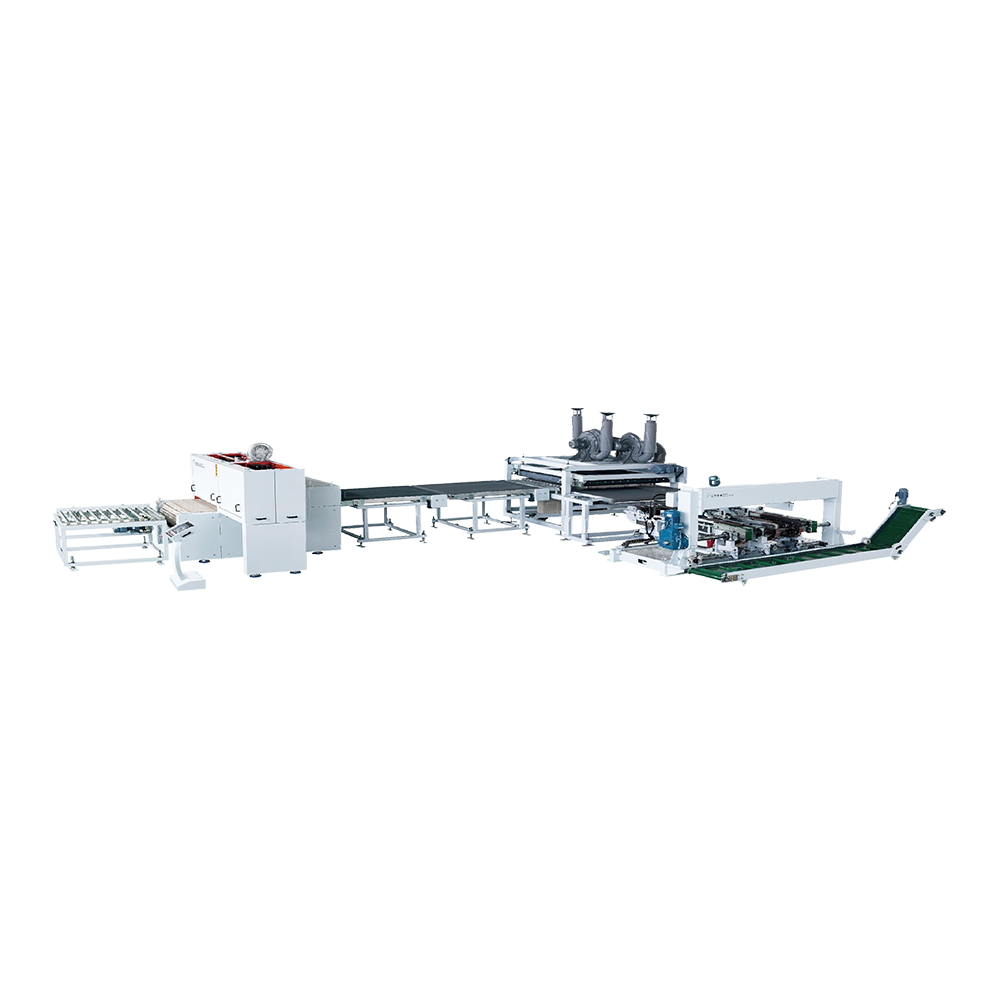

Key to this adjustability is the integration of advanced far-infrared heating technology and a sophisticated hot air circulation system. These features not only expedite the drying process but also ensure that each groove, regardless of its depth, is evenly coated. The combination of energy-efficient systems minimizes consumption, making the painting process not only faster but also more environmentally friendly. By utilizing water-based paints, the machines align with modern sustainability practices, offering a greener alternative to traditional methods.

The precision built into these machines allows for fine-tuned adjustments, ensuring that they can handle various groove depths with ease. This flexibility positions HAWK as a leader in the field, able to cater to the ever-evolving needs of its clients. Whether a manufacturer requires a machine for standard applications or one that can handle more complex requirements, HAWK’s customization options ensure that no project is too ambitious.

For industries where efficiency and quality are paramount, HAWK’s Laminate Floor V-Groove Painting Machine stands as a testament to engineering excellence and versatility. The company's ability to provide tailored solutions—paired with cutting-edge technology—ensures that customers can achieve consistent, high-quality results, regardless of groove depth.

HAWK Machinery China Co., Ltd. continues to lead the way in floor treatment technology, providing solutions that combine innovation, sustainability, and precision. With their adaptable WPC Floor V-Groove Painting Machine, they offer a solution that not only meets but exceeds the demanding needs of modern flooring manufacturing.