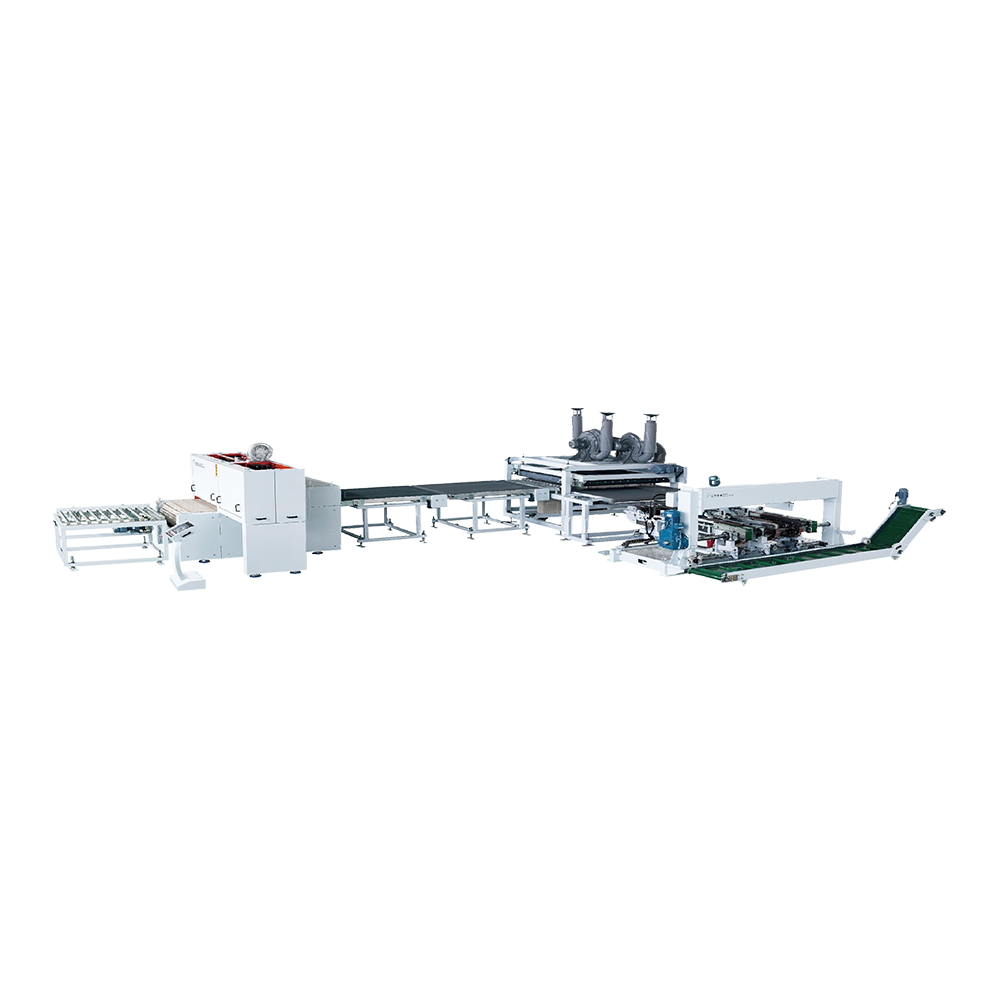

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsIn today’s fast-paced industrial world, optimizing production is key. One powerful way to achieve this is through the use of a PVC cutting machine. From cutting plastic sheets to slicing PVC pipes with ease, these versatile machines are revolutionizing how businesses handle polyvinyl chloride materials.

The Importance of PVC Cutting Equipment

PVC, or polyvinyl chloride, is one of the most widely used plastics due to its durability and flexibility. To work with this material effectively, a PVC cutter is essential. These plastic cutting machines come in many forms—manual, semi-automatic, and fully automated—each tailored to different industrial applications.

A PVC cutting machine ensures clean, uniform cuts, which are vital in industries such as construction, packaging, and signage production. Whether it’s a PVC pipe cutting tool or an advanced CNC cutting system, precision and reliability are guaranteed.

How PVC Cutting Machines Improve Workflow

The implementation of a PVC sheet cutter in your production line brings notable improvements:

Speed: Automated PVC cutters can process dozens or even hundreds of pieces per hour.

Consistency: With minimal human intervention, every cut remains identical, reducing quality issues.

Safety: Modern PVC cutting equipment includes safety guards and automated controls, reducing the risk of workplace accidents.

Types of PVC Cutters Available

Manual PVC Cutters: Ideal for simple, on-site jobs. These are compact and budget-friendly.

Semi-Automatic Cutting Machines: Suitable for medium-scale operations that require flexibility and efficiency.

CNC PVC Cutting Systems: High-end machines designed for precision cutting and mass production.

Each type of PVC cutter serves a unique role, making it essential to match the machine type with your specific business needs.

Selecting the Best PVC Cutting Machine

To find the ideal PVC cutting tool, consider the following:

Material Thickness: Choose a plastic cutter that matches the range of PVC thicknesses you work with.

Volume of Work: High production volumes benefit from automated or CNC PVC cutting machines.

Budget and ROI: While higher-end machines cost more upfront, they offer long-term savings through improved output and reduced waste.