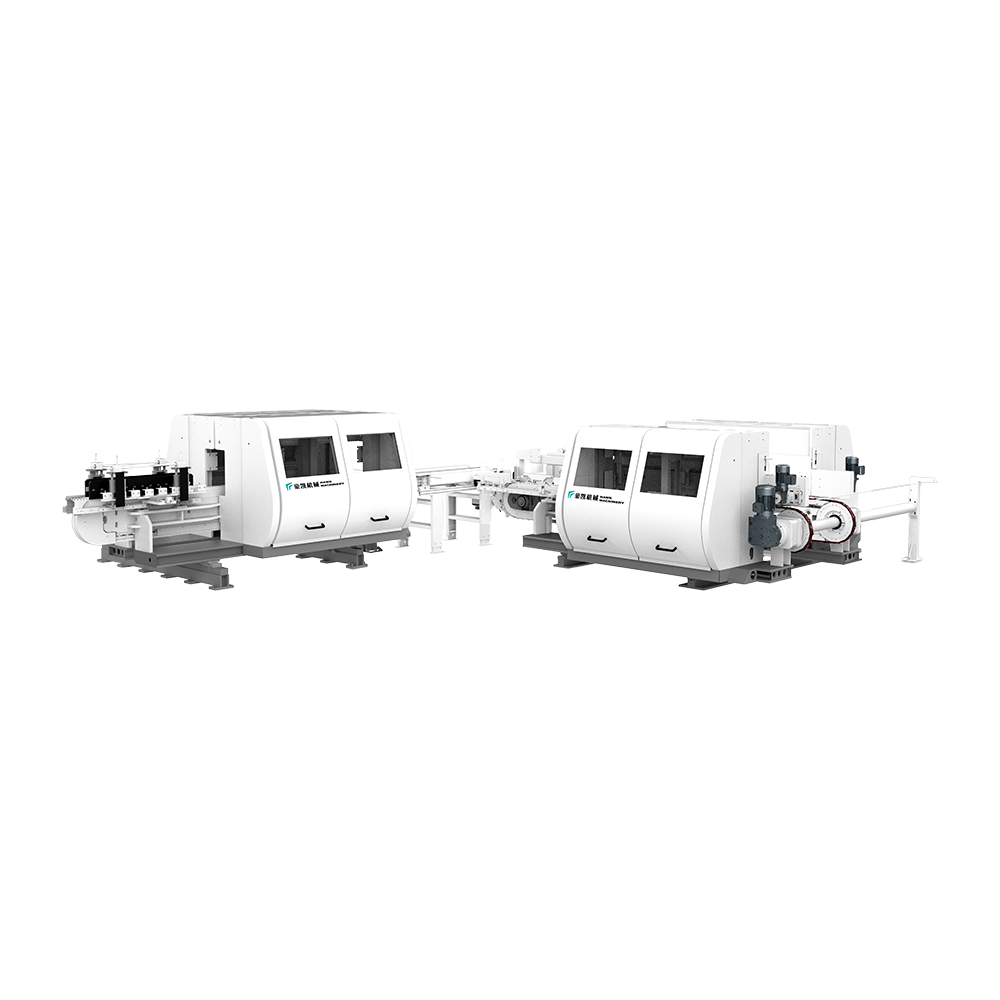

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsThe Floor Beveling Machine is a specialized piece of equipment designed to create precise, angled edges, or "bevels," on flooring materials. While the term "beveling machine" is often used broadly in industrial metalwork, when focused on flooring, this machine plays a critical role in enhancing the aesthetic, authenticity, and fit of various floor types, particularly engineered wood, laminate, and resilient flooring (like LVT/SPC).

The primary function of the Floor Beveling Machine is to remove a uniform strip of material from the edge of a floor plank or tile. This process serves several key purposes:

Aesthetic Enhancement: The bevel creates a distinct groove between installed floor panels, mimicking the look of traditional solid wood planks where each board is individually defined. This significantly enhances the visual appeal and authenticity of the finished floor.

Camouflage: By creating a shadow line, the bevel helps to hide minor imperfections or slight variations in height between adjacent floor pieces.

Preparation for Joint Technology: Bevels are often engineered alongside locking systems to ensure a clean, tight, and gap-free fit when panels are joined together.

Modern Floor Beveling Machines incorporate advanced features to deliver speed, precision, and versatility in production.

The machine can be configured to produce a variety of bevel profiles to meet market trends and design specifications:

Micro Bevel: A very small, shallow angle that offers a subtle definition between planks.

Deep/V-Groove Bevel: A more pronounced, deeper angle that provides a strong, traditional plank look.

Irregular Bevel: This mimics the natural, slightly uneven look of hand-crafted or distressed wood, adding a layer of authenticity to the product.

Pressed/Painted Bevel: In some resilient flooring lines, the bevel is combined with a pressing technology or a paint line to apply a contrasting color (often for a grout line effect on tile products) or a matte finish.

The precision of the bevel is achieved through highly calibrated tooling:

Rotary Milling Heads: These heads are equipped with specialized cutting tools (often carbide inserts) that precisely mill the edge profile onto the flooring panel as it passes through the machine.

High-Speed Operation: Machines are designed for high throughput, operating at production-line speeds to process thousands of linear feet of material per hour, making them indispensable in mass-production environments.

High-end Floor Beveling Machines feature sophisticated control systems:

CNC Controls: Computer Numerical Control (CNC) allows operators to precisely program and recall settings for different bevel angles, depths, and panel thicknesses, ensuring absolute consistency across production batches.

Automatic Adjustment: Some systems offer automated tool change or adjustment, drastically reducing downtime when switching between different floor product designs.

Trace Tracking: For non-linear or specially shaped panels, advanced machines can incorporate systems to read the geometry of the part and adjust the beveling tool path accordingly.

The Floor Beveling Machine is an essential piece of equipment across different sectors of floor manufacturing:

Laminate Flooring: Used to create the characteristic V-groove that is standard in most laminate products.

Engineered Wood: Crucial for profiling the top layer veneer, ensuring the finished floor has the distinct look of solid planks.

Resilient Flooring (LVT/SPC/WPC): Essential for adding a realistic, finished edge, especially for tile-look products that require a realistic 'grout' bevel effect.

Stone/Tile Edging: While technically a "stone edging beveling machine," specialized variants apply the same principle to create polished or rounded edges on stone and ceramic tiles.

The Floor Beveling Machine is a testament to the manufacturing sector's commitment to quality and realism in flooring design. It is the technology that transforms a plain panel into a defined, authentic-looking floorboard, offering manufacturers a crucial competitive edge in an increasingly design-focused market.