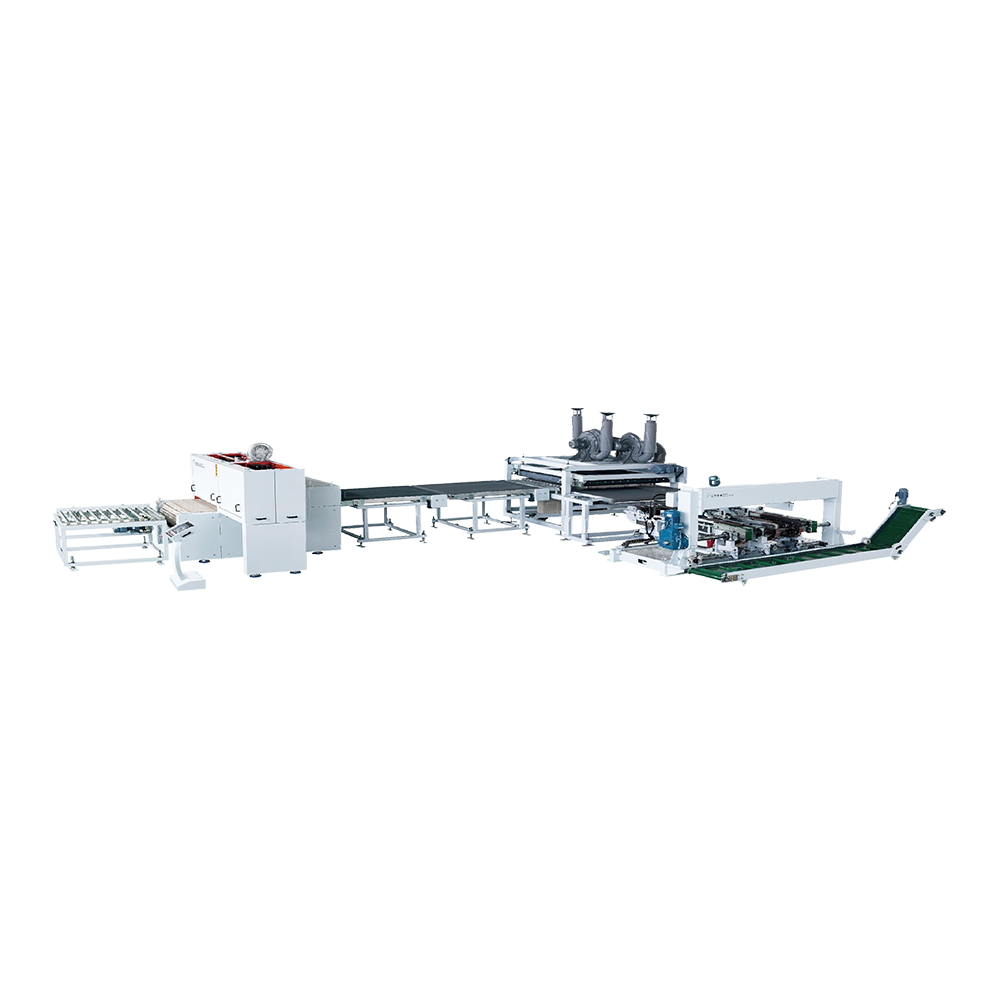

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsThe global demand for efficient, durable, and cost-effective flooring has driven significant innovation in manufacturing technology. At the heart of this revolution is the Floor Extrusion Machine, a specialized piece of industrial equipment that fundamentally transforms raw materials into finished or semi-finished flooring products. These machines are pivotal in the production of various flooring types, including luxury vinyl plank (LVP), wood-plastic composite (WPC), and Stone Plastic Composite (SPC) flooring.

A Floor Extrusion Machine operates on the principle of extrusion, a process where raw thermoplastic or composite materials are melted and then forced through a shaped die under high pressure. This die dictates the final profile or width of the flooring sheet or plank.

The typical process within the machine involves several key steps:

Material Feeding: Raw materials—often in the form of pellets, powders, or chips, which may include PVC resin, stabilizers, and fillers—are fed into a hopper.

Melting and Mixing: The material enters the barrel of the extruder, where it is heated and homogenized by a rotating screw (or twin screws). This action creates a molten, uniform mixture.

Die Forming: The molten material is pushed through a precisely shaped die, which forms it into a continuous sheet or profile.

Calibration and Cooling: The hot sheet immediately passes through a calibration unit (often a series of rollers or plates) to achieve the exact thickness and dimensional stability required. This is followed by rapid cooling to solidify the product.

Ancillary Processes: Depending on the product, the line may also include laminating a decorative film, adding a protective wear layer, or surface embossing before the final cutting and stacking.

The efficiency and precision of a Floor Extrusion Machine are largely determined by the screw design and the temperature control system, which must be calibrated to the specific rheological properties of the composite material being processed.

The versatility of the Floor Extrusion Machine allows manufacturers to produce a wide array of modern flooring solutions:

SPC is one of the fastest-growing flooring segments, known for its high density and waterproof core. The extrusion process for SPC involves using a high-torque twin-screw extruder to process the heavy composition of lime powder (calcium carbonate) and PVC resin. The Floor Extrusion Machine produces the rigid core board, which is then often laminated with the design layer and wear layer in-line.

WPC flooring incorporates a foaming agent, making the final product lighter and softer underfoot than SPC. The machine must carefully manage the heating and pressure to achieve the desired foamed core structure during extrusion, ensuring a consistent cell structure and material distribution.

While some LVT/LVP is produced via a calendering process, the extrusion method is increasingly used for the core layers, particularly for rigid core products, offering higher output and excellent thickness control.

Modern Floor Extrusion Machine technology focuses on optimizing output, reducing energy consumption, and enhancing product quality:

Co-Extrusion: Some advanced machines utilize co-extrusion to simultaneously extrude multiple layers of different materials, such as extruding the rigid core and an attached underlayment layer in a single pass. This streamlines production and improves interlayer bonding.

High-Efficiency Motors: The adoption of servo and inverter-controlled motors has increased the energy efficiency of the driving components, reducing operational costs.

Automated Control Systems: Sophisticated PLC (Programmable Logic Controller) systems now govern nearly every parameter—from feeding rate and barrel temperature to cooling speed—ensuring minute-by-minute quality control and minimizing material waste.

In conclusion, the Floor Extrusion Machine is an indispensable tool in modern flooring manufacturing. Its ability to process complex composite materials with speed and precision is the foundation for producing the high-quality, durable, and aesthetically diverse flooring products that define today's global market.