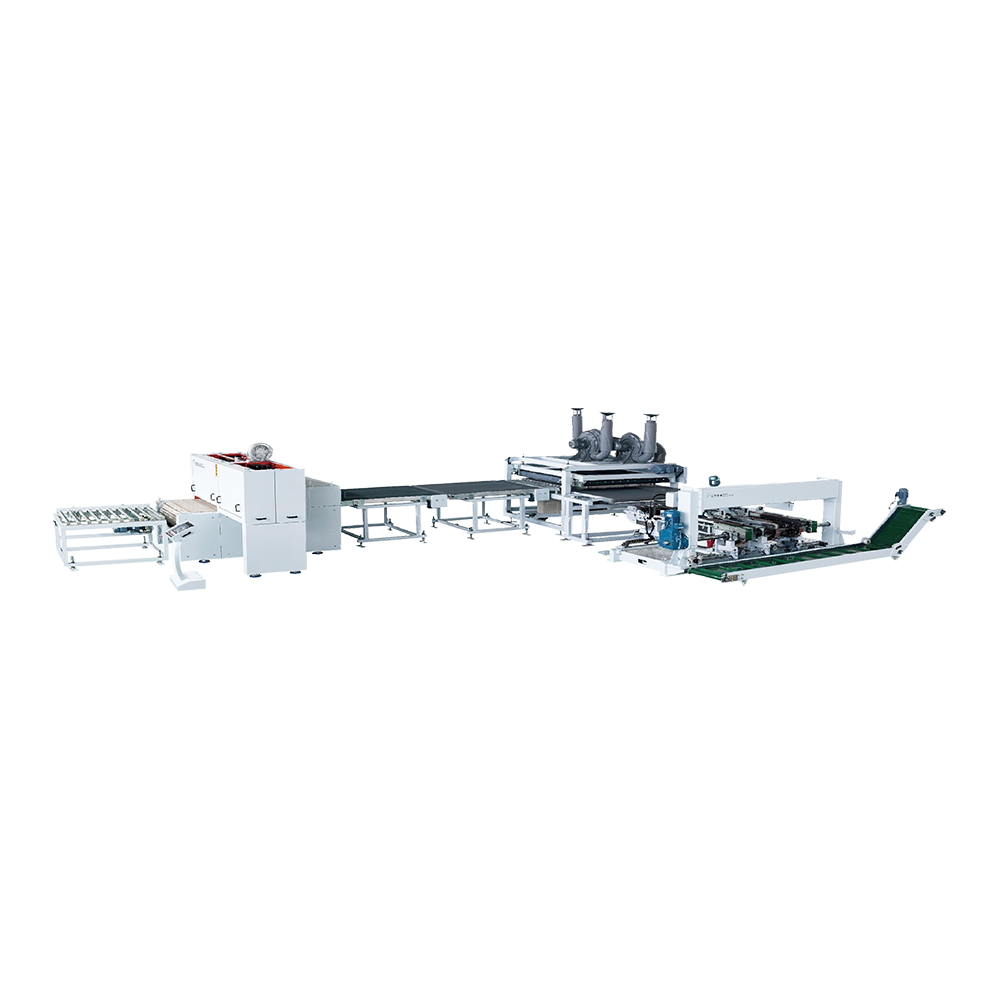

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsPVC, or polyvinyl chloride, is one of the most widely used plastics in the world. Known for its durability, resistance to chemicals, and versatility, it’s a staple in industries ranging from construction and plumbing to signage and advertising. As the demand for custom PVC products has grown, so has the need for advanced cutting technology. This is where the PVC cutting machine has become an indispensable tool.

A PVC cutting machine is not a single type of device but a category of specialized equipment designed to precisely and efficiently cut PVC in various forms, from rigid sheets and foam boards to flexible films and pipes. Unlike manual cutting methods, which can be slow, inconsistent, and wasteful, these machines offer unparalleled accuracy, speed, and repeatability.

The choice of machine depends heavily on the specific application and the type of PVC being cut.

CNC Routers: For thick, rigid PVC sheets and foam boards, a CNC router is the go-to solution. These machines use a high-speed rotating spindle with a cutting bit to carve or mill through the material. They are controlled by computer numerical control (CNC) software, allowing for complex shapes, precise cuts, and detailed engraving. They are widely used in the sign-making, furniture, and manufacturing industries.

Laser Cutters: A laser cutting machine uses a focused laser beam to melt, burn, or vaporize the PVC material. This method is exceptionally clean, fast, and ideal for creating intricate designs without physical contact. The non-contact nature of laser cutting minimizes material deformation and provides a smooth, polished edge. However, care must be taken with PVC as it releases hydrogen chloride gas when heated, which is corrosive and requires proper ventilation and a filtration system.

Knife Cutting Machines (Digital Cutters): For flexible or thin PVC materials like vinyl banners, films, or sheets, a digital knife cutting machine is the perfect fit. These devices use a computer-controlled blade to cut through the material with high precision. They are commonly used in the signage, textile, and packaging industries for creating decals, stencils, and flexible packaging components.

When selecting a PVC cutting machine, several factors are crucial for optimizing performance and safety:

The widespread adoption of the PVC cutting machine has revolutionized manufacturing and design processes. It has enabled mass customization, allowing businesses to produce complex, one-of-a-kind products with the efficiency of mass production. It has also reduced material waste, improved product quality, and significantly shortened production times.

From bespoke PVC pipe fittings to giant outdoor advertisements and custom architectural panels, the PVC cutting machine is a testament to the power of combining material science with automated technology. Its ability to deliver precision, speed, and versatility makes it a cornerstone of modern fabrication, driving innovation and efficiency across countless industries.