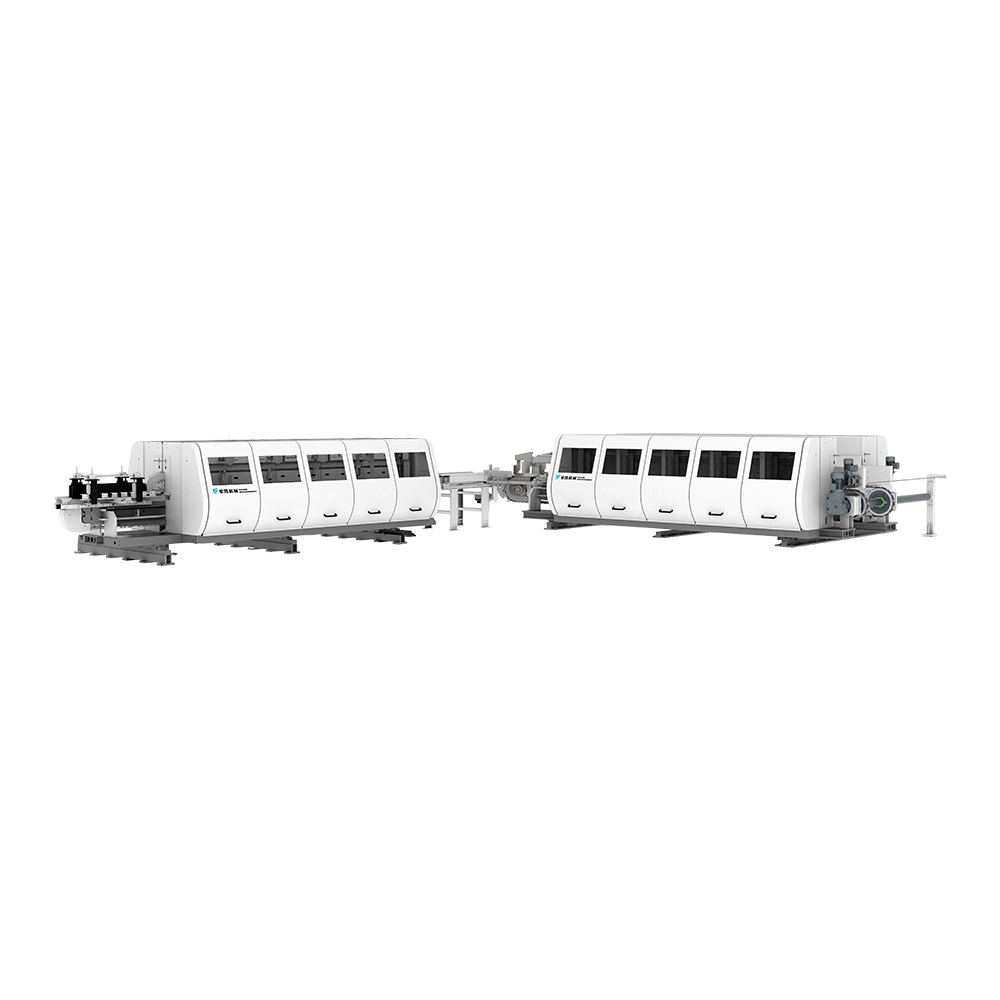

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsFloor slotting machines, also known as floor grinders, scarifiers, or planers, are specialized pieces of equipment designed to modify concrete and other hard flooring surfaces. They achieve this by abrading, grinding, or milling the top layer, creating grooves, trenches, or textured finishes. These machines are indispensable in a wide range of industries, offering solutions for both functional and aesthetic flooring needs.

Floor slotting machines are utilized across numerous sectors due to their versatility and efficiency. Here are some of their primary applications:

One of the most critical applications is enhancing safety. By creating textured surfaces, these machines significantly increase the coefficient of friction, reducing the risk of slips and falls. This is particularly vital in:

Industrial Facilities: Warehouses, factories, and manufacturing plants often deal with spills (oil, water, chemicals) that can make floors extremely hazardous. Slotting machines create channels that help drain liquids and provide grip.

Commercial Kitchens: High-traffic areas with grease and water accumulation benefit immensely from grooved floors, preventing accidents among staff.

Livestock Facilities: Farms and dairies use slotting to provide better traction for animals, preventing injuries and improving animal welfare.

Public Walkways and Ramps: Outdoor areas prone to rain or ice can be made safer for pedestrians with a non-slip finish.

Floor slotting machines are essential for preparing concrete surfaces for subsequent treatments. This includes:

Coating and Overlay Adhesion: By creating a profile on the concrete surface, slotting machines improve the mechanical bond between the substrate and new coatings (e.g., epoxy, polyaspartic) or overlays. This prevents delamination and ensures longevity.

Removal of Existing Coatings: Old paint, sealers, mastic, thin-set, and even some adhesives can be effectively removed, creating a clean canvas for new applications.

Leveling and Repair: Uneven concrete slabs or those with minor imperfections can be leveled or prepared for patch repairs, creating a smooth and consistent base.

Contaminant Removal: Grinding can remove dirt, oil, grease, and other contaminants embedded in the concrete, ensuring a clean and sound surface.

In environments where liquid management is crucial, floor slotting machines are used to cut precise drainage channels. This is vital in:

Food and Beverage Processing Plants: Regular washdowns require efficient drainage to prevent water accumulation and maintain hygiene standards.

Car Washes and Garages: Channels direct water and chemicals away from working areas, preventing pooling.

Loading Docks and Exterior Areas: Managing rainwater or spills to prevent flooding and ensure safety.

Beyond their functional benefits, floor slotting machines can be used to achieve unique decorative effects:

Terrazzo and Polished Concrete Preparation: Initial grinding stages for these popular flooring types involve slotting machines to expose aggregates and create a smooth, reflective surface.

Creating Patterns and Designs: With skilled operators, machines can be used to cut specific patterns or designs into the concrete, adding an artistic touch to commercial or residential spaces.

Exposing Aggregates: Controlled grinding can expose the decorative aggregates within the concrete mix, creating a natural and appealing finish.

For more aggressive applications, floor slotting machines can be used for:

Reducing Slab Height: In instances where floor height needs to be lowered slightly, these machines can remove a uniform layer of concrete.

Preparing for Demolition: Breaking up smaller sections of concrete or creating control joints before more extensive demolition.

Aggregate Exposure for Architectural Finishes: Aggressive grinding can expose a larger portion of the aggregate for specific architectural aesthetics.

The term "floor slotting machine" can encompass several types of equipment, each designed for specific tasks:

Grinders/Polishers: Primarily used for surface preparation, leveling, and achieving polished finishes. They use rotating discs with abrasive segments.

Scarifiers/Planers: More aggressive machines that use rotating flails or cutters to chip away at the concrete surface. Ideal for heavy-duty material removal, leveling, and creating deep profiles.

Groovers: Specialized machines with diamond blades set to cut precise, uniform grooves for drainage or anti-slip purposes.

Efficiency: They quickly and effectively modify large areas, saving significant time and labor compared to manual methods.

Precision: Modern machines offer excellent control over depth and profile, ensuring consistent results.

Versatility: A single machine can often perform multiple tasks by changing the tooling.

Durability: Treated floors exhibit enhanced durability and longevity, reducing maintenance needs in the long run.

Safety: Directly contributes to safer working and public environments.

Floor slotting machines are indispensable tools in modern construction and maintenance, offering a comprehensive range of solutions from enhancing safety and preparing surfaces to creating aesthetic finishes and managing liquids. Their ability to precisely and efficiently modify concrete and other hard floors makes them a vital asset across diverse industries, contributing significantly to the functionality, safety, and longevity of flooring systems.