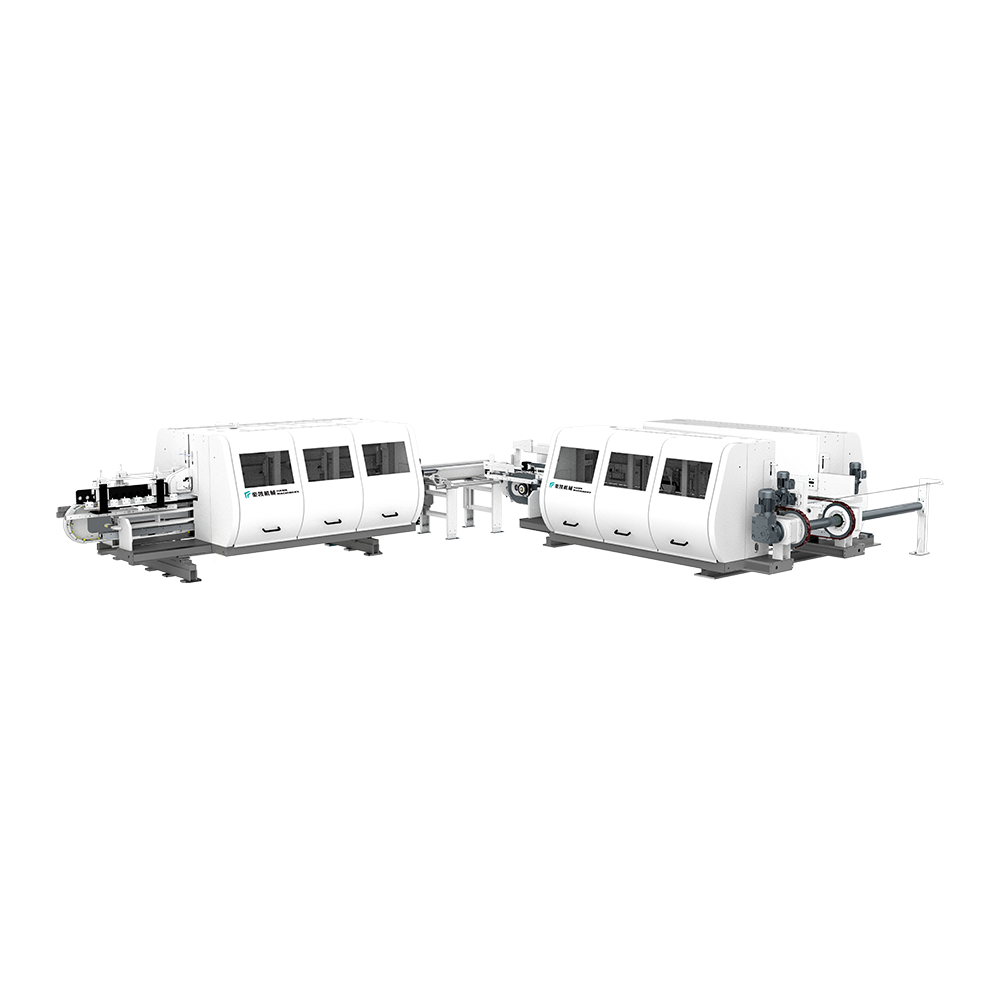

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsWhen you're in the market for a double end tenoner machine, understanding the specifications is crucial. These aren't just numbers; they're the details that determine a machine's capability, efficiency, and suitability for your specific woodworking needs. A quality double end tenoner machine can be a game-changer for high-volume, precision work, but a poor choice can lead to bottlenecks and inconsistent results.

This is arguably the most important spec. It includes the maximum and minimum working width and the maximum and minimum working length. The working width determines how wide a panel or piece of material the double end tenoner machine can process, while the working length dictates the shortest and longest pieces it can handle. For instance, a machine with a working width of 100-3,000mm is incredibly versatile for various furniture components, from narrow rails to wide panels.

The number and arrangement of spindles directly impact the machine's functionality. A basic double end tenoner machine might have just one or two spindles per side (one for trimming, one for tenoning), while more advanced models can have multiple spindles for specialized operations like scoring, grooving, or sanding. The spindle motor power (in kW or HP) is also critical. Higher power allows for deeper cuts and faster feed speeds, especially with dense hardwoods.

The feed system's specifications dictate the machine's speed and precision. Look for the feed speed range (m/min). A variable feed speed is a must-have, as it allows you to optimize for different materials and operations. A robust chain-feed system with hold-downs is essential for keeping material stable during processing, ensuring a clean, precise cut. The chain's pad material and width can also affect grip and longevity.

Modern double end tenoner machines often come with sophisticated control systems. A CNC interface or a touchscreen HMI (Human Machine Interface) makes setting up jobs and changing parameters far more efficient. Look for features like automatic positioning of the fences and spindles, which drastically reduces setup time and minimizes human error. Some machines even offer data logging and diagnostic capabilities for better maintenance and troubleshooting.

Beyond the basic trim and tenon, a double end tenoner machine can perform a variety of cuts. Check the specifications for the maximum tenon length and thickness, the maximum cutting depth, and the tooling diameter and bore. The ability to use different types of cutters, such as profile heads, grooving tools, or sanding drums, adds significant value and versatility.

Don't overlook the physical specs. The machine dimensions (length x width x height) and weight are important for planning your workshop layout. A heavier machine often indicates a more rigid and stable frame, which translates to less vibration and greater cutting accuracy.

Choosing the right double end tenoner machine means looking past the sales pitch and diving into the details. By carefully evaluating these specifications, you can find a machine that not only fits your budget but also meets your production demands for years to come.