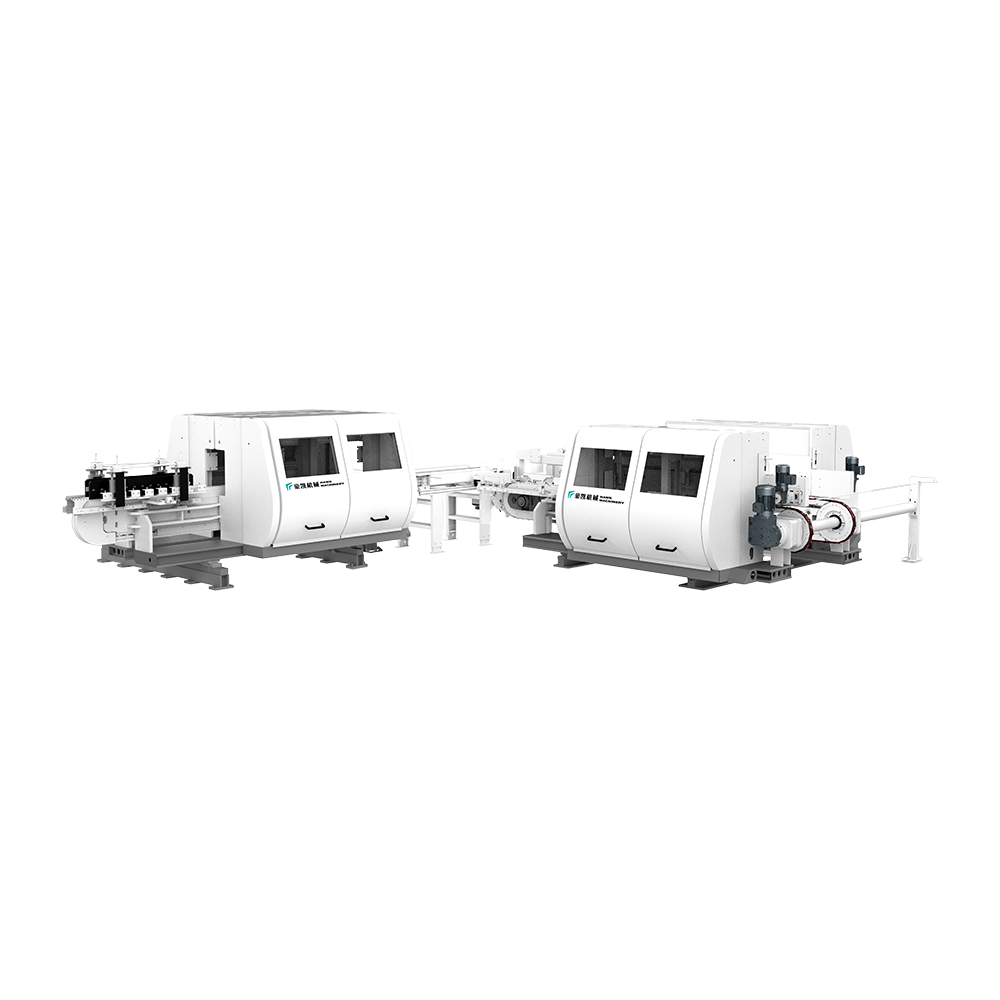

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsA floor extrusion machine is a versatile piece of industrial equipment used to manufacture various flooring products. Its ability to process a wide range of raw materials is key to its utility. The choice of material directly impacts the final product's durability, appearance, and cost.

WPC is a highly popular material for floor extrusion. It's a composite of wood fiber or flour and a thermoplastic, such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC). A floor extrusion machine can blend these components to create a product that combines the aesthetic of wood with the durability and moisture resistance of plastic. WPC flooring is often used for decking, but it's also a common material for interior floorboards and tiles, valued for its low maintenance and resistance to rot.

PVC is one of the most widely used plastics in the world, and it's a core material for floor extrusion. A floor extrusion machine can process PVC to create a variety of flooring types, from solid PVC floor tiles to luxury vinyl planks (LVP) and sheets. PVC flooring is known for its excellent water resistance, ease of cleaning, and affordability. Additives can be mixed with the PVC resin to control properties like flexibility, color, and fire resistance, making it highly customizable.

The rising demand for sustainable manufacturing has made recycled plastics a significant material for floor extrusion. A floor extrusion machine can be engineered to process flakes or pellets from recycled materials like high-density polyethylene (HDPE) or low-density polyethylene (LDPE). Using recycled plastics helps reduce waste and lower production costs. Flooring made from recycled materials is often used in industrial or outdoor settings where durability and environmental impact are more critical than a high-end finish.

To reduce the use of plastic and create a more eco-friendly product, some floor extrusion machine models can process natural fibers like rice husks, bamboo, or even coconut coir. These fibers are mixed with a binder or polymer to create a biocomposite material. This type of flooring is valued for its unique texture, reduced environmental footprint, and potential for use in specific niche markets.

In short, the adaptability of a floor extrusion machine allows manufacturers to innovate with a diverse array of materials, from traditional composites to recycled and bio-based alternatives. This flexibility enables the production of a wide range of flooring products tailored to different performance requirements, costs, and sustainability goals.