Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsA 3 rip saw machine is a specialized piece of woodworking equipment designed to streamline the process of breaking down wide timber planks into multiple narrower strips in a single pass. Unlike a standard single-blade rip saw, this multi-blade configuration allows for significantly higher throughput by performing three parallel cuts simultaneously. This setup is particularly valued in high-volume furniture manufacturing, flooring production, and lumber mills where speed and precision are non-negotiable. By utilizing three circular saw blades mounted on a common arbor, the machine ensures that the resulting strips are perfectly parallel, reducing the need for secondary squaring operations.

Modern iterations of the triple blade rip saw often feature variable speed feeders and laser guide lights to help operators align the wood grain for the best yield. The goal of using a 3 rip saw machine is not just speed, but material optimization. By carefully positioning the blades, a shop can maximize the usable "clear" wood from a board while cutting away defects like knots or cracks. This efficiency makes it a cornerstone for any workshop looking to scale up production without compromising on the quality of the raw material preparation.

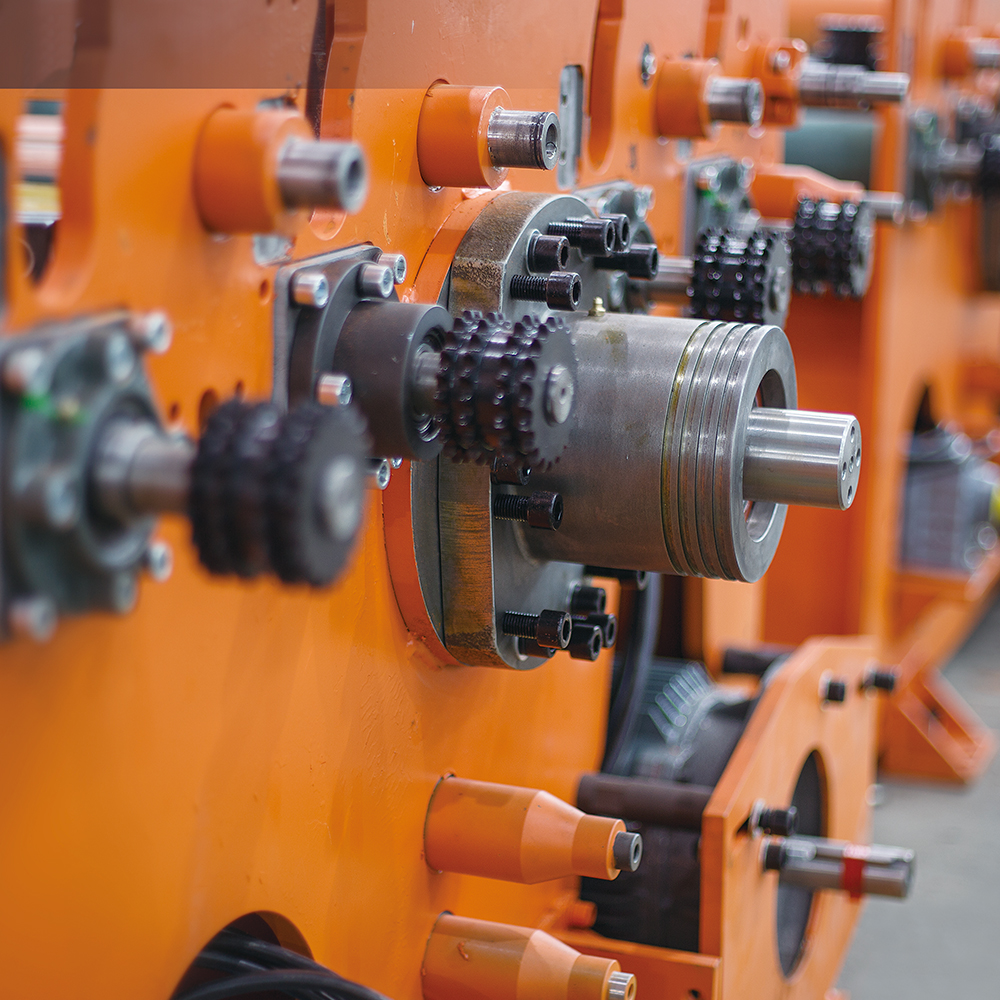

The heart of the 3 rip saw machine is the arbor, which must be precision-engineered to eliminate vibration. In a three-blade setup, spacers are used between the blades to set the width of the cut. Some high-end machines feature adjustable "floating" blades that can be moved via a control panel, while others rely on fixed spacers for consistent, repetitive production runs.

Safety is paramount when operating a multi-blade system. Because three blades are contacting the wood at once, the risk of kickback is higher than with a single blade. Therefore, these machines are equipped with multiple rows of anti-kickback fingers and heavy-duty pressure rollers to keep the lumber firmly seated against the conveyor bed during the entire cutting process.

Choosing between different saw configurations depends on your daily output requirements. While a single-blade saw offers flexibility for custom widths, a 3 rip saw machine provides the sweet spot between high-speed industrial output and manageable machine footprints for medium-sized shops.

| Machine Configuration | Typical Pass Rate | Primary Advantage |

| Single Rip Saw | 1 strip per pass | Maximum Versatility |

| 3 Rip Saw Machine | 3 strips per pass | High Speed & Efficiency |

| Gang Rip Saw (Multiple) | 5+ strips per pass | Mass Industrial Volume |

Maintaining a three-blade rip saw requires a bit more attention than a standard table saw. Because the blades work in unison, if one blade becomes dull faster than the others, it can cause the wood to "pull" or drift, leading to inaccurate cuts and potential motor strain. Consistent maintenance ensures the longevity of the machine and the safety of the operator.

The quality of the cut from your 3 rip saw machine is heavily dependent on the type of blades installed. For most ripping operations, a flat-top grind (FTG) blade with a low tooth count is ideal, as it clears sawdust quickly and prevents burning. When working with softer woods, you might choose a blade with a slightly higher tooth count for a cleaner finish, but for industrial ripping, heat dissipation is the priority. Many operators prefer chrome-coated or carbide-tipped blades, as they stay sharp significantly longer when processing thousands of linear feet of lumber. It is also wise to keep matched sets of three blades so that they can be sharpened and replaced together, maintaining a consistent diameter and cutting depth across the entire arbor.