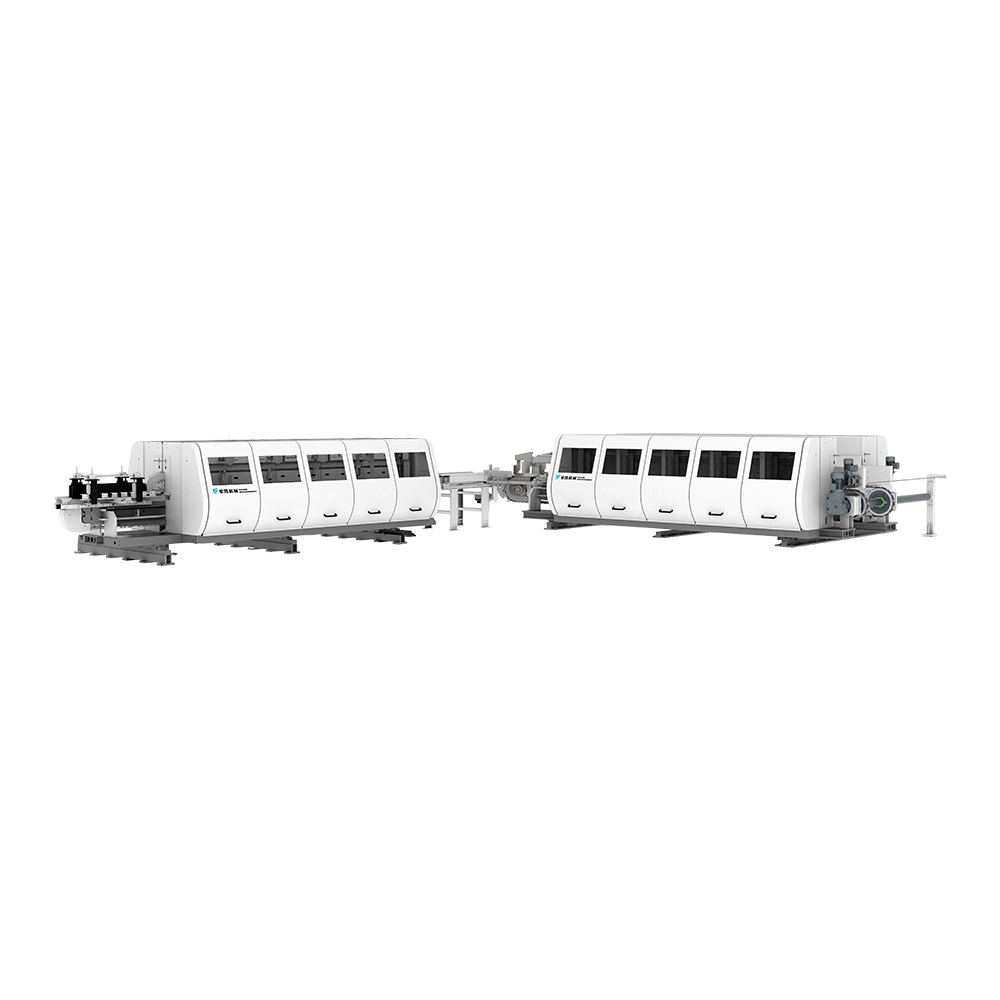

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsA floor slotting line is the backbone of modern laminate, SPC, and LVT flooring production. This automated system is designed to take raw flooring planks and precision-cut the intricate tongue-and-groove or click-lock profiles required for seamless installation. The process involves high-speed milling spindles that must operate with extreme accuracy, often within tolerances of a fraction of a millimeter. Without a finely tuned slotting line, planks may fail to lock together properly, leading to structural gaps or "peaking" in the finished floor. By integrating advanced sensors and carbide-tipped tooling, these lines ensure that every single piece of flooring is uniform and ready for high-traffic use.

The workflow typically starts with an automated feeding system that aligns the planks before they enter the longitudinal and transverse profiling stations. During this journey, the floor slotting machinery removes material in stages to prevent splintering or chipping, which is especially critical for brittle materials like Stone Plastic Composite (SPC). Modern lines are also equipped with dust extraction ports to maintain a clean environment, ensuring that debris doesn't interfere with the cutting heads or the optical sensors monitoring the quality of the slots.

The milling stations are where the heavy lifting happens. Each station is equipped with multiple motors that can be adjusted to create different types of click systems, such as Valinge or Uniclic profiles. These motors must be robust enough to handle the abrasive nature of flooring cores while maintaining high RPMs for a smooth finish.

To achieve a straight cut, the plank must be held perfectly still while moving at high speeds. High-friction belts and overhead pressure rollers work in tandem to prevent the plank from shifting. If the tension is too loose, the slotting will be uneven; if it's too tight, you risk damaging the decorative surface layer of the flooring.

When selecting a floor slotting line, the production capacity is often the most important metric. Depending on the complexity of the locking profile and the material density, speeds can vary significantly. Below is a comparison of typical performance metrics for various types of slotting setups:

| Machine Type | Average Speed (m/min) | Best Material Suitability |

| Standard Laminate Line | 60 - 80 | HDF / MDF |

| High-Speed SPC Line | 40 - 60 | Stone Plastic Composite |

| Heavy Duty LVT Line | 30 - 50 | Luxury Vinyl Tile |

To keep your flooring slotting machinery running at peak performance, a proactive maintenance schedule is non-negotiable. Because these machines deal with high-friction cutting and fine dust, wear and tear happen faster than in standard woodworking. Regular attention to the tooling and the mechanical alignment will save thousands in avoided downtime and wasted material.

The physical placement of your floor slotting line within the factory can impact overall efficiency. Ideally, the line should be positioned directly after the cooling or curing area to minimize material handling. Since flooring planks are heavy in bulk, using automated loading arms or "stackers" at the end of the slotting line reduces manual labor and prevents edge damage that can occur when stacking by hand. Furthermore, ensuring that there is ample space around the milling stations allows technicians to perform tool changes quickly, keeping the "up-time" of the floor slotting line as high as possible.