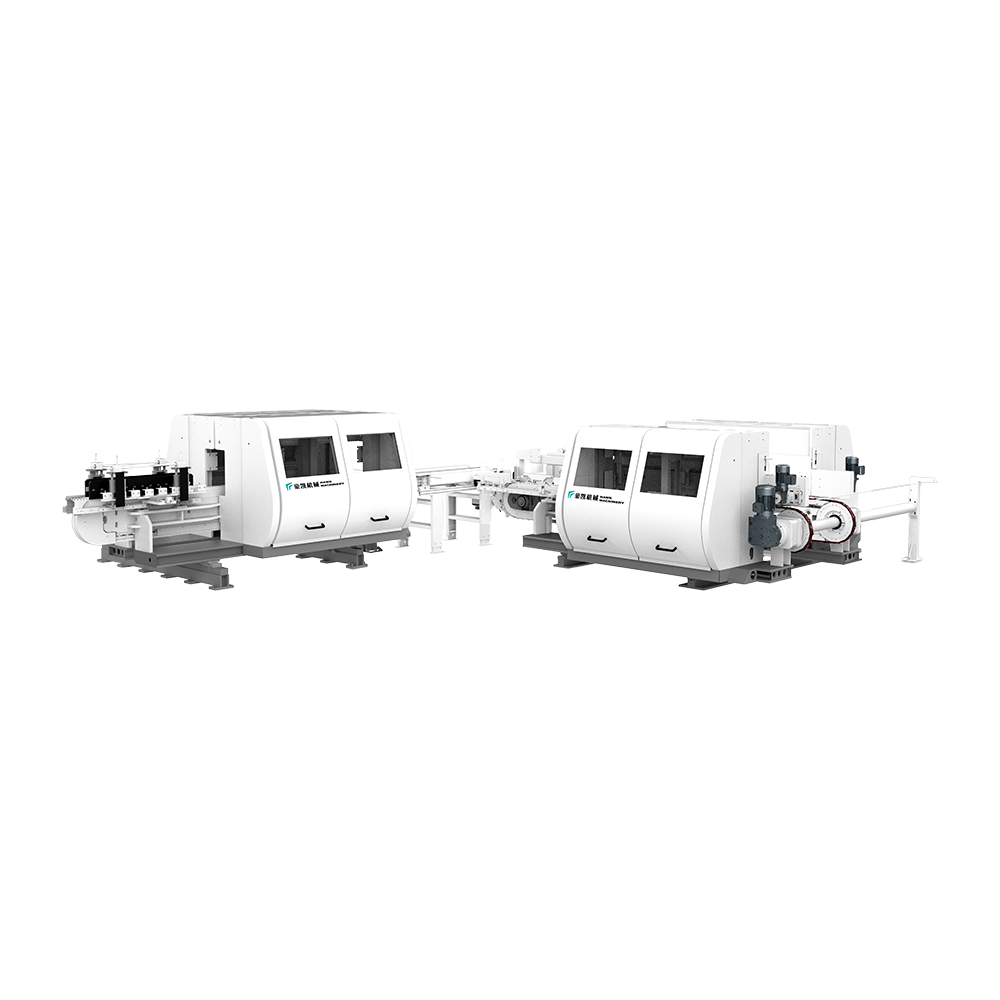

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsIn the competitive world of resilient flooring manufacturing, the finishing touches often dictate the market value of the product. An LVT flooring trimming machine is an essential piece of equipment designed to remove excess material and burrs from the edges of Luxury Vinyl Tiles after the initial cutting or pressing stage. This process ensures that every plank or tile meets exact dimensional specifications, which is vital for the "click-lock" systems or tight-fit installations common in modern interior design. Without high-quality trimming, the integrity of the flooring joint can be compromised, leading to gaps or uneven surfaces during installation.

Modern trimming systems utilize high-speed rotating blades and precision sensors to track the edge of the material. By integrating an LVT edge finishing system into the production line, manufacturers can achieve a level of consistency that manual trimming simply cannot match. This automation not only speeds up the manufacturing cycle but also significantly reduces the rate of material waste, as the machine can be calibrated to trim only the absolute necessary amount of overflow.

The heart of a high-performance floor tile edge trimmer is its control interface. Most industrial-grade models feature PLC (Programmable Logic Controller) systems that allow operators to adjust trimming depths and speeds based on the thickness of the LVT material. This flexibility is crucial because LVT varies in density and wear-layer thickness, requiring different blade pressures to avoid chipping or melting the vinyl.

Trimming vinyl creates fine particulates that can be hazardous to workers and damaging to sensitive machinery. Professional LVT flooring trimming machines come equipped with integrated vacuum extraction ports. These systems pull debris away from the cutting head immediately, keeping the workspace clean and preventing dust from interfering with the precision sensors or contaminating the finished surface of the flooring planks.

When selecting an LVT trimming solution, it is important to understand how different specifications impact your daily output. The following table highlights the typical performance metrics for standard vs. high-output industrial trimming machines.

| Feature | Standard Model | High-Output Model |

| Processing Speed | 15-25 m/min | 40-60 m/min |

| Thickness Range | 2mm - 6mm | 2mm - 12mm |

| Blade Material | Alloy Steel | PCD (Polycrystalline Diamond) |

| Adjustment Type | Manual Handwheel | Digital Touchscreen/Auto |

Switching to a specialized LVT flooring trimming machine offers several long-term benefits for flooring factories and fabrication shops. These advantages extend beyond simple speed, impacting the overall quality and brand reputation of the flooring produced.

To keep an LVT flooring trimming machine running at peak performance, a regular maintenance schedule must be followed. Because LVT contains PVC and calcium carbonate (in the case of SPC/LVT hybrids), the abrasive nature of the material can wear down even the hardest blades over time. Operators should inspect blade sharpness daily and ensure that the lubrication systems for the guide rails are functioning correctly to prevent friction-related heat buildup.

Furthermore, the electrical components should be kept free of vinyl shavings. Periodically checking the alignment of the feed rollers will prevent the "snaking" of material through the machine, which can cause uneven trims or machine jams. Investing in high-quality diamond-tipped blades, while more expensive initially, typically results in a lower cost-per-linear-meter of trimmed flooring due to their superior resistance to the abrasive fillers found in LVT products.