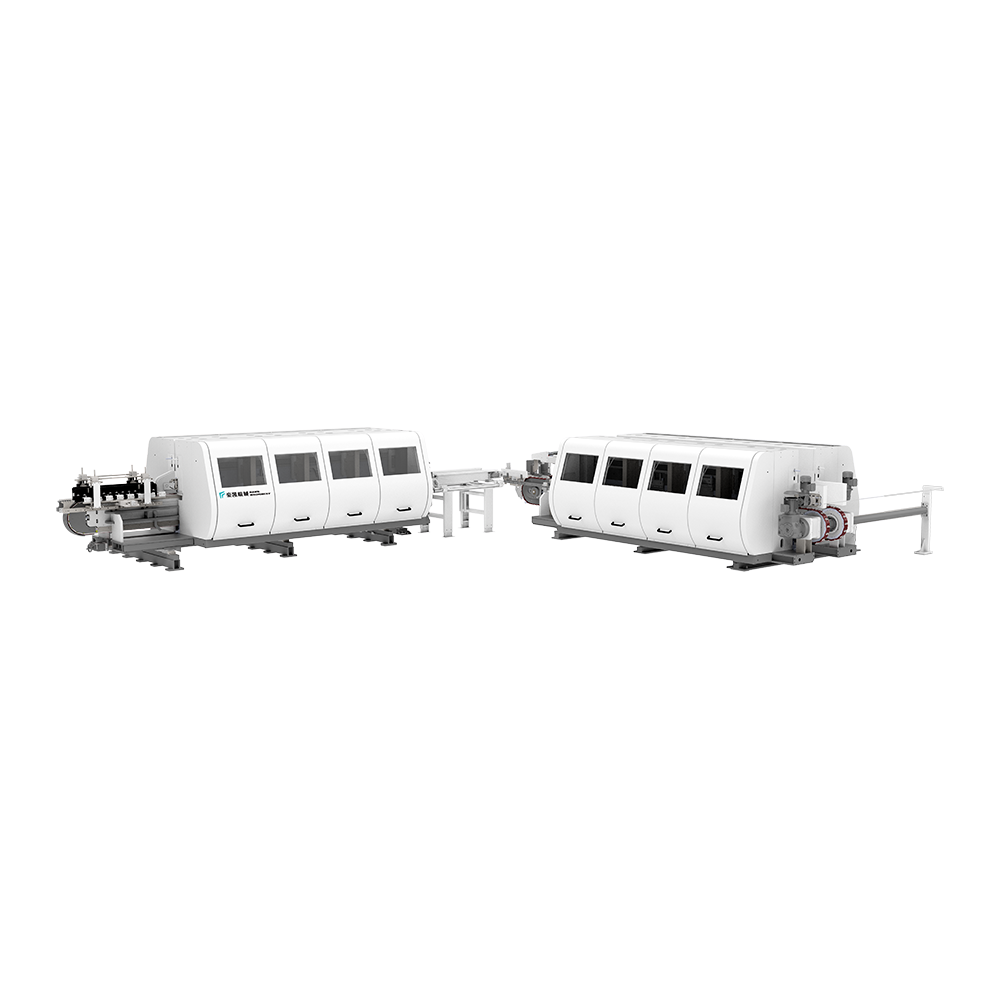

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsFloor extrusion machines are specialized equipment designed to produce high-quality flooring profiles efficiently and consistently. They play a critical role in the manufacturing of vinyl, PVC, WPC, and other synthetic flooring materials. These machines combine advanced extrusion technology, precise temperature control, and automated systems to ensure uniformity, durability, and aesthetic quality in the final flooring products. Investing in a reliable floor extrusion machine significantly enhances production efficiency while minimizing material wastage.

A typical floor extrusion machine consists of several key components that work in unison to deliver precise results. Understanding these components helps manufacturers optimize their operations and ensure consistent product quality.

The extruder is the heart of the machine, responsible for melting and homogenizing raw materials. Modern extruders feature high-efficiency screw designs that reduce energy consumption and improve material mixing, allowing for the production of complex flooring profiles with consistent thickness and density.

The die shapes the molten material into the desired flooring profile, while the calibration system ensures dimensional accuracy. Advanced calibration systems often include vacuum sizing, cooling tanks, and adjustable supports to maintain uniformity across long production runs.

After extrusion, the flooring passes through cooling systems that solidify and stabilize the profile. Cooling methods vary depending on the material but typically include water baths, air cooling, or a combination of both. Conveying units move the product efficiently through the line, minimizing defects and handling errors.

Floor extrusion machines come in various types depending on the flooring material and production requirements. Selecting the right type is essential for maximizing efficiency and product quality.

To achieve the best results with a floor extrusion machine, manufacturers need to focus on several operational factors. Temperature control, screw speed, material feed rate, and die precision must be carefully adjusted. Automation and monitoring systems further enhance consistency, reduce downtime, and lower energy consumption. Regular maintenance and timely replacement of wear-prone components, such as screws and barrels, are also critical to sustaining high productivity.

A robust quality control system ensures that the flooring meets dimensional, mechanical, and aesthetic standards. Key inspection points include thickness uniformity, surface smoothness, color consistency, and edge precision. Some manufacturers integrate online inspection systems that detect defects in real-time, allowing for immediate corrections without halting production.

Innovation in floor extrusion machines is moving towards higher automation, energy efficiency, and sustainability. Emerging trends include:

Floor extrusion machines are the backbone of modern flooring manufacturing, combining precision engineering, automation, and material science. Choosing the right machine, optimizing operational parameters, and maintaining strict quality control ensure high productivity and superior flooring products. As technology evolves, these machines will continue to offer greater efficiency, sustainability, and versatility for flooring manufacturers worldwide.