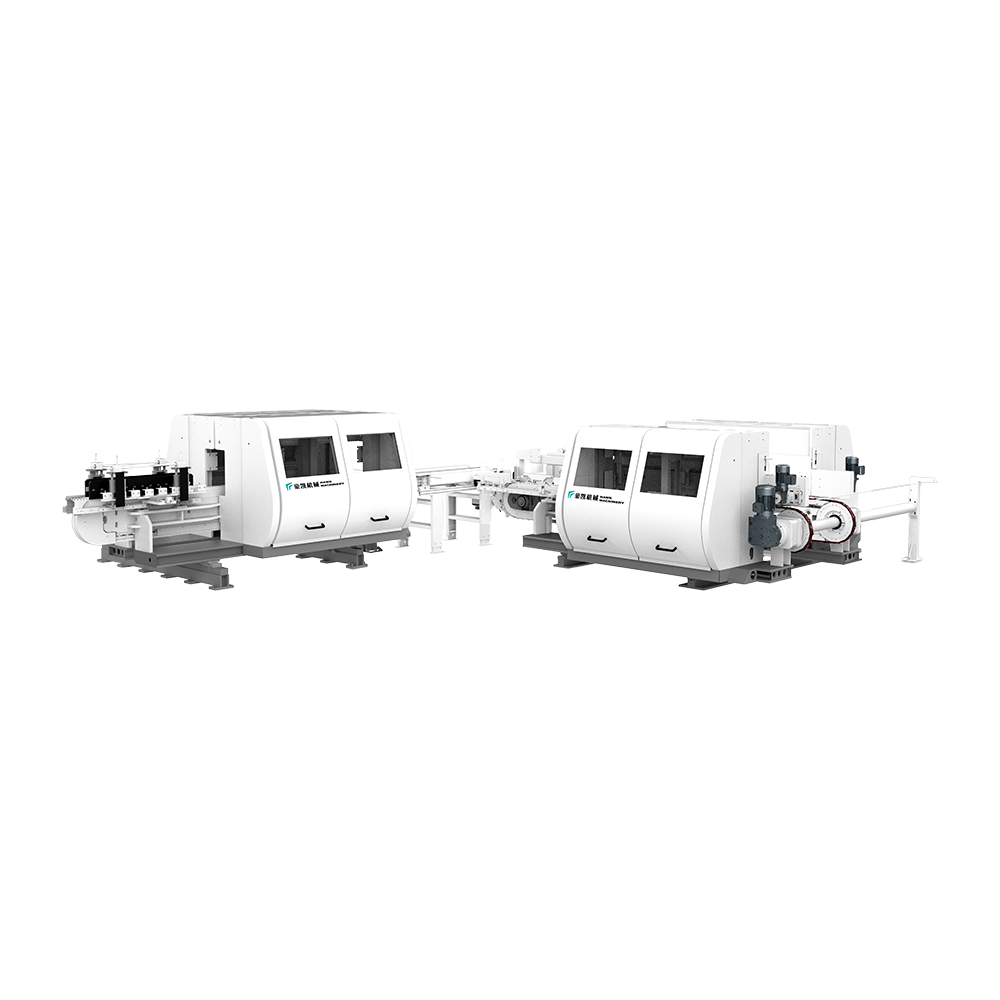

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsWhen it comes to installing LVT (Luxury Vinyl Tile) flooring, achieving a flawless, professional finish is all about precision. While many tools can cut vinyl, the dedicated LVT Flooring Trimming Machine is an invaluable piece of equipment that elevates the quality and efficiency of any installation project. This specialized tool, also known as a vinyl flooring cutter or LVT tile cutter, is designed specifically to handle the unique properties of luxury vinyl, providing clean, straight cuts that are difficult to replicate with traditional utility knives or saws.

Luxury Vinyl Tile and Plank are far more rigid and durable than older vinyl products. They often feature a composite core and a wear layer that can be challenging to cut cleanly, especially in tight spaces or around complex shapes. Trying to use a utility knife often results in jagged edges, uneven cuts, and wasted material. A conventional saw, while powerful, can be messy, creating dust and noise and potentially chipping the material.

The LVT Flooring Trimming Machine solves these problems with its precise cutting mechanism. Most models operate like a large guillotine, using a heavy-duty, hardened steel blade to shear through the material in a single, swift motion. This method provides several key advantages:

Clean, Straight Cuts: The guillotine action produces a perfectly straight, splinter-free edge. This is crucial for creating tight, seamless joints where planks meet walls or other obstacles.

Dust-Free Operation: Unlike power saws, these machines generate no sawdust, making for a cleaner and healthier work environment. This is especially beneficial for indoor installations.

Quiet and Convenient: The manual operation is virtually silent, allowing for work in occupied spaces without causing a disturbance. It's also highly portable and doesn't require electricity.

Speed and Efficiency: A professional vinyl flooring cutter can trim a plank in seconds, significantly speeding up the installation process compared to manual scoring and snapping.

Not all LVT tile cutters are created equal. When selecting a machine, consider the following features to ensure you get the best tool for the job:

Cutting Capacity: Check the maximum width and thickness the machine can handle. It should accommodate the most common LVT plank sizes (e.g., 6, 7, 9 inches wide) and the thickness of the material you're using.

Adjustable Angle: Many high-end models offer the ability to make angled or miter cuts. This is extremely useful for installations in rooms with odd angles or for creating decorative patterns.

Integrated Measuring Guide: A built-in ruler or measuring fence allows for quick and accurate cuts without needing a separate tape measure.

Durable Blade and Construction: Look for a machine with a high-quality, long-lasting blade and a sturdy, robust frame. This ensures the tool will withstand the rigors of frequent use on job sites.

For professional flooring installers, a quality LVT Flooring Trimming Machine isn't just a convenience; it's a wise investment. The time saved, the reduction in material waste, and the superior quality of the finished installation all contribute to increased productivity and customer satisfaction. While the initial cost may seem high, the long-term benefits in efficiency and professionalism make it an indispensable part of any installer's toolkit. It’s the difference between a good job and a truly exceptional one.