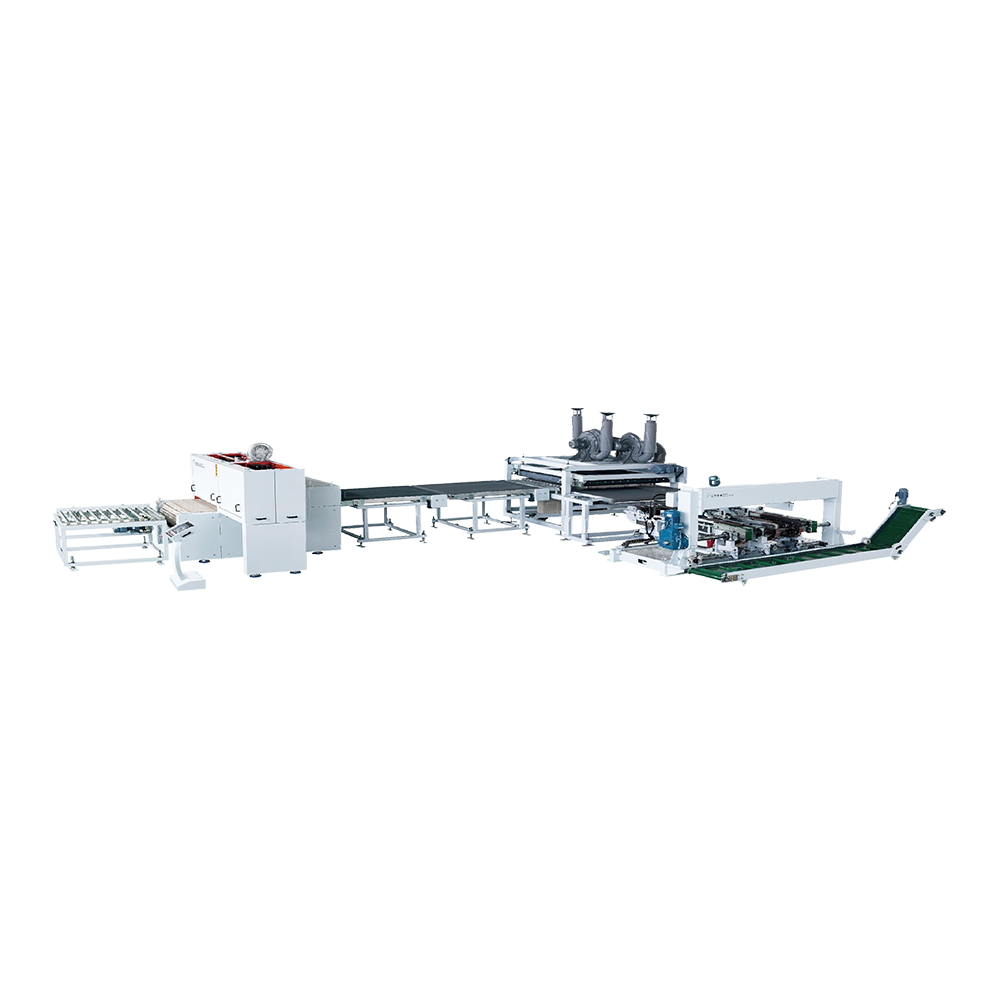

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsIn an era defined by precision and speed, the flooring industry is undergoing a significant transformation. At the heart of this change is a technological marvel that is redefining how we manufacture and install modern floors: the PVC Floor CNC Cutting Machine. This isn't just a new tool; it's a paradigm shift, moving the industry from labor-intensive, often imprecise methods to a streamlined, highly accurate, and incredibly efficient automated process.

For years, the complexity of flooring designs was limited by the constraints of manual cutting. Intricate patterns, custom logos, and unique borders were either too time-consuming, too expensive, or simply impossible to create with a hand knife. The PVC Floor CNC Cutting Machine has shattered these limitations.

Unleashing Creative Freedom: Architects and designers can now push the boundaries of their creativity. The machine's ability to execute complex, non-linear cuts with perfect accuracy means that custom geometric patterns, artistic inlays, and brand logos can be integrated directly into the floor design. This level of customization allows for truly bespoke flooring solutions that can define a space, from a corporate lobby to a luxury home.

Perfecting Seams and Inlays: The most noticeable benefit to the end consumer is the flawless finish. A PVC Floor CNC Cutting Machine ensures that every piece fits together seamlessly, eliminating the unsightly gaps and misalignments that can plague a manually installed floor. This precision is especially critical for intricate inlay work where every millimeter matters for a professional, high-end look.

The impact of the PVC Floor CNC Cutting Machine goes far beyond the aesthetic. It is a powerful engine for optimizing the entire manufacturing and installation workflow.

Eliminating Human Error: Manual cutting is inherently susceptible to human error—a slight slip, a miscalculation in measurement, or a dull blade can ruin an expensive piece of material. A CNC machine operates from a digital file, executing the same perfect cut every single time. This consistency dramatically reduces material waste and the need for re-cutting, saving both time and money.

Massive Gains in Productivity: Imagine a flooring company needing to cut hundreds of identical shapes for a large commercial project. A manual process would take days of painstaking work. A PVC Floor CNC Cutting Machine can complete the same task in a fraction of the time, operating continuously and at high speeds. This increased throughput allows manufacturers to take on larger projects and meet tighter deadlines, significantly boosting their competitive advantage.

Integration with Modern Software: The machine’s power is multiplied by its integration with advanced software. Using sophisticated nesting algorithms, the software automatically arranges the design patterns on the material sheet in the most efficient way possible, maximizing yield and minimizing waste. This smart approach to material management is a game-changer for businesses focused on cost control and sustainability.

The benefits of the PVC Floor CNC Cutting Machine extend all the way to the installation site.

Pre-cut, Ready-to-Install Pieces: Since all the pieces are cut with precision off-site, installers receive a ready-to-lay kit. This eliminates the need for messy, noisy, and time-consuming on-site cutting, which is often a major source of dust and disruption.

Reduced Labor and Installation Time: With perfectly cut pieces, the installation process becomes a matter of assembly rather than a constant process of measuring and trimming. This greatly reduces labor costs and shortens project timelines, allowing contractors to complete jobs faster and move on to the next one.

In conclusion, the PVC Floor CNC Cutting Machine is a foundational technology for the modern flooring industry. It is not just about cutting materials; it is about cutting costs, cutting waste, and most importantly, cutting new paths for design and efficiency. As the industry continues to evolve, this powerful tool will remain at the forefront, defining a new standard for quality, creativity, and performance.