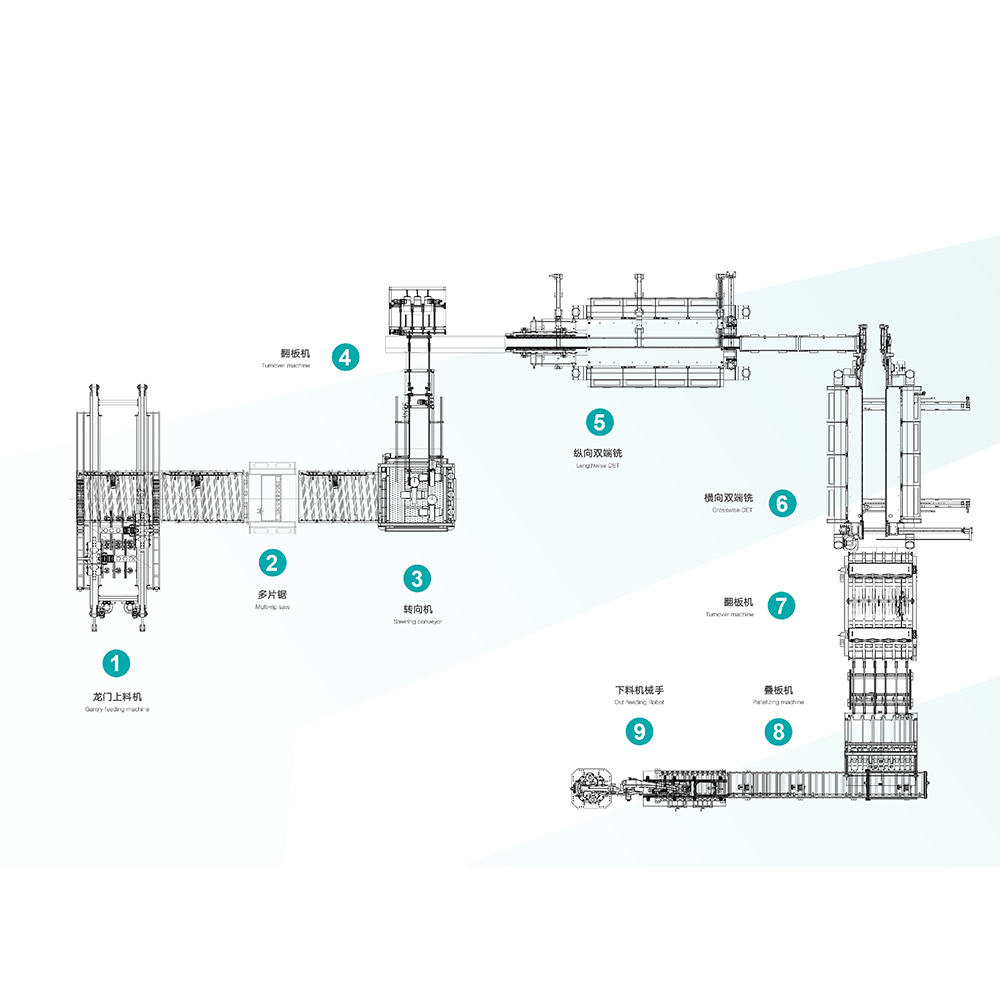

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsA WPC Floor Production Line is a sophisticated system that transforms raw materials into high-quality WPC (Wood Plastic Composite) flooring. The technical parameters of this line are not just numbers; they are the core specifications that define its performance, efficiency, and the quality of the final product. For anyone looking to invest in or operate such a line, a deep understanding of these parameters is crucial for making informed business decisions.

The extruder is the heart of the entire line. Its parameters are the most critical determinants of the line's output and stability.

Extruder Type: The most common type for WPC flooring is the conical twin-screw extruder. The twin-screw design provides excellent compounding and plasticizing for PVC and wood flour mixtures.

Screw Diameter: This is a key indicator of the extruder's capacity. It is typically expressed as a pair of numbers, such as φ80/156, representing the outer and inner diameters of the screws. A larger screw diameter generally correlates with a higher output.

Main Motor Power: Measured in kilowatts (kW), this parameter indicates the power of the main motor that drives the screws. A higher motor power provides more torque, allowing the machine to handle higher outputs and more viscous material. Typical values can range from 110 kW to 250 kW or more.

L/D Ratio (Length-to-Diameter): This ratio, which compares the length of the screw to its diameter, is a measure of the effective length of the screw. A higher L/D ratio (e.g., 30:1 to 36:1) allows for better mixing, plasticizing, and degassing of the raw materials, which is essential for producing uniform, high-quality products.

These are the most direct measures of the line's production efficiency.

Production Capacity (Output): This is the ultimate benchmark, typically measured in kilograms per hour (kg/h). Depending on the extruder size and product thickness, the output can range from 300 kg/h for smaller lines to over 1,500 kg/h for high-capacity lines.

Extrusion Speed: Measured in meters per minute (m/min), this parameter indicates how fast the finished board is pulled from the extruder. It's directly related to the output and the thickness of the board. A typical speed might be 1-10 m/min, with thicker boards requiring a slower speed.

The equipment following the extruder ensures the extruded sheet is properly formed, cooled, cut, and stacked.

Die Head Width: This parameter determines the maximum width of the WPC sheet that can be produced. Standard widths are often 1,220 mm or 1,300 mm to accommodate standard plank sizes.

Calibration Unit: This unit, equipped with vacuum pumps and cooling plates, sets the final shape and thickness of the board. Key parameters include the number of cooling plates/zones and the cooling method (e.g., water spray).

Haul-off Machine: This machine pulls the board through the calibration unit. Its technical parameters include pulling speed and pull force (kN), which must be sufficient to ensure stable, consistent transport without deforming the product.

Cutting Machine: This unit automatically cuts the sheet to the desired length. Key parameters are the cutting length range and cutting precision, which are crucial for consistent final product size.

These parameters are essential for factory layout and operational cost planning.

Total Installed Power: This is the sum of the power consumption of all motors, heating elements, and auxiliary equipment. It is measured in kW and dictates the required power supply for the entire line. A typical line can have a total installed power of 200 kW to 600 kW.

Overall Dimensions: The length, width, and height of the entire WPC production line dictate the required factory floor space. A standard line can be anywhere from 20 to 30 meters in length and require an operational area of 50 to 100 square meters or more, depending on the layout.

Understanding these technical parameters allows manufacturers to accurately estimate production costs, plan factory layouts, and select the right machinery to meet their specific business goals.