Wood-Plastic Composite (WPC) flooring has emerged as a premier solution in modern construction and interior design, lauded for its durability, water-resistance, and environmental profile. The large-scale manufacturing of this advanced material relies entirely on the sophistication and efficiency of the WPC Floor Production Line. This automated equipment transforms raw materials into high-performance, multi-layered flooring planks with precision and speed, underpinning the material’s rapid adoption across residential and commercial sectors.

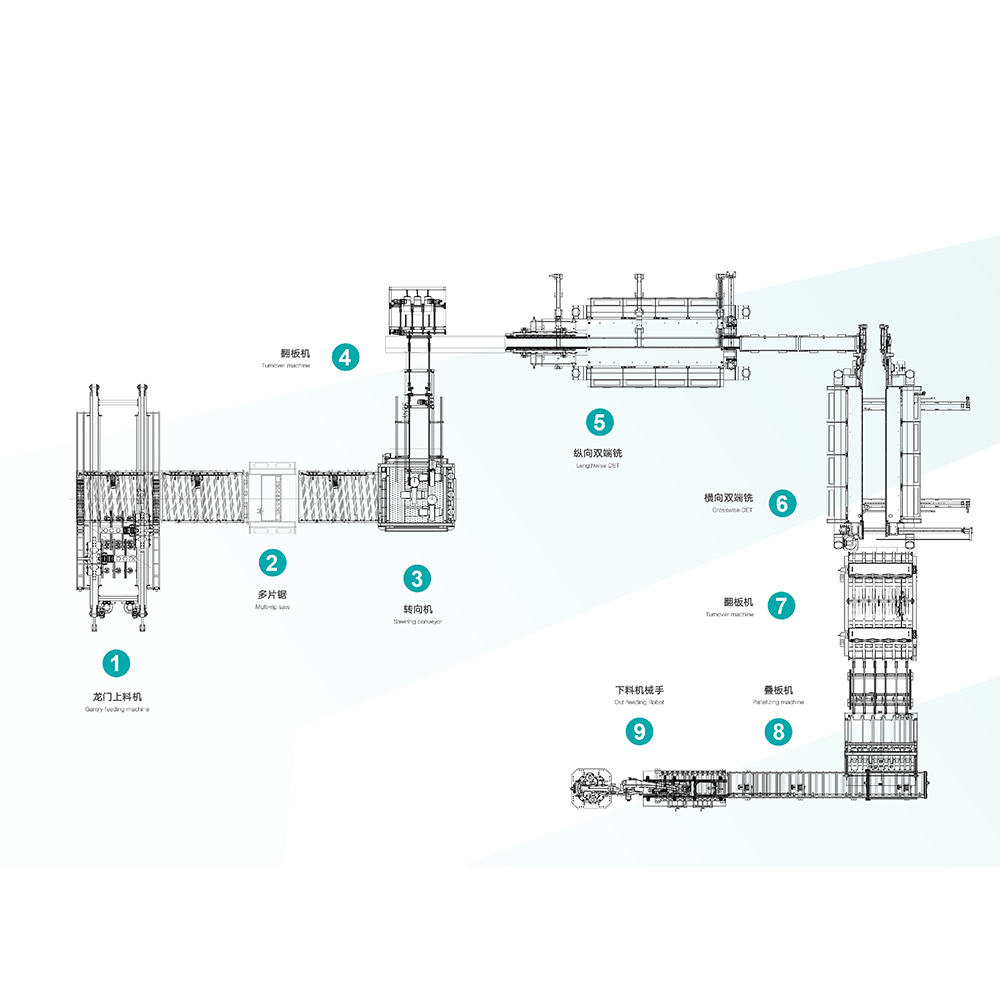

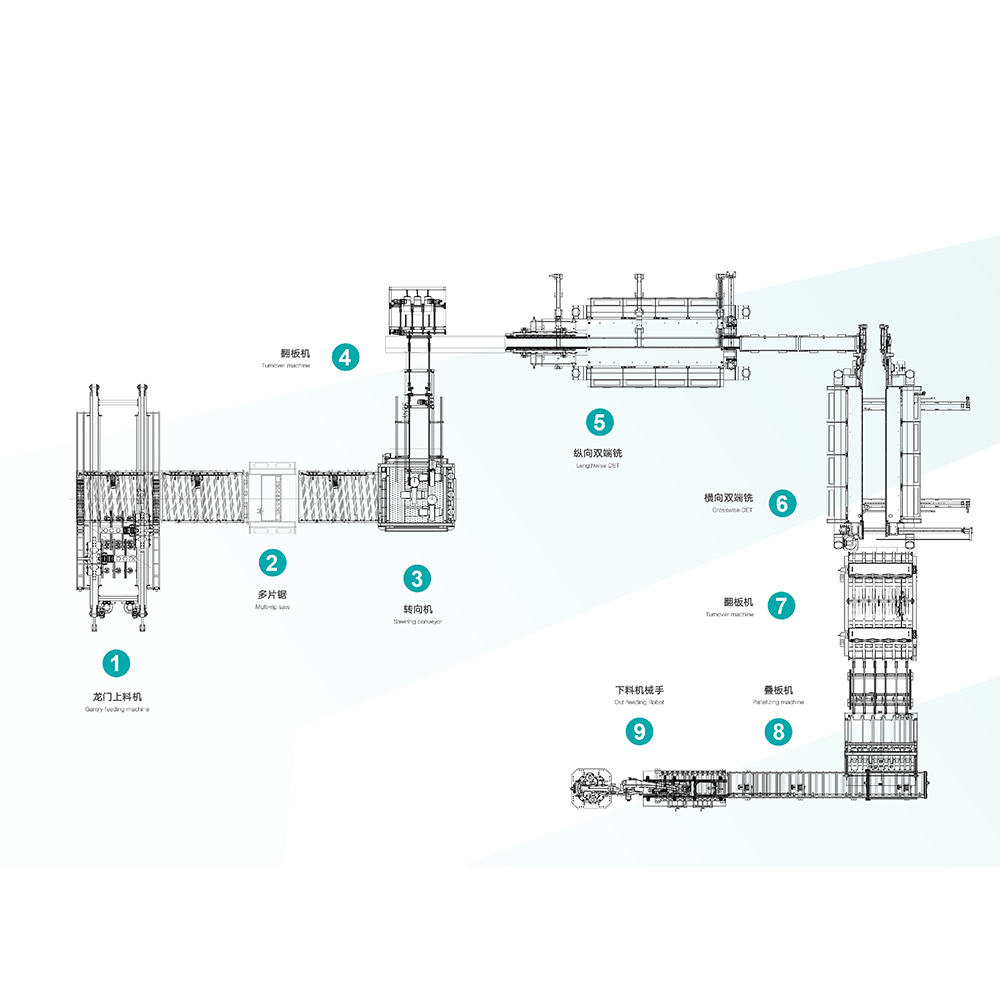

Core Components of the WPC Floor Production Line

A modern WPC Floor Production Line is an intricate network of specialized machinery, each performing a critical function in the continuous manufacturing process. The line is broadly categorized into material preparation, extrusion, and finishing systems.

- Raw Material Preparation and Mixing: The process begins with carefully proportioned raw materials, primarily PVC (Polyvinyl Chloride) resin and wood flour or other cellulose fibers, along with various additives like stabilizers, plasticizers, and colorants. A high-speed mixer is essential for ensuring a perfectly homogeneous blend of these components, which directly dictates the final product’s quality and consistency.

- Extrusion System (The Heart of the Line): This is where the core WPC layer is formed.

- A Conical Twin-Screw Extruder is typically used due to its high efficiency in plasticizing and compounding the high-fill WPC mixture. It heats and intensely mixes the material.

- The melted mixture is forced through a custom-designed Mould and Calibrator to give the WPC layer its exact cross-sectional structure, thickness, and width. A vacuum calibration system is often employed here to ensure dimensional stability and surface quality.

- Cooling and Hauling: Following calibration, a multi-stage cooling system (often using water) is crucial to solidify the material rapidly and prevent warping or deformation. The Hauling Machine or Haul-Off Unit then pulls the continuous profile through the line at a precise, controlled rate.

- Cutting and Finishing: An automatic Cutter trims the continuous board into planks of the specified length, often utilizing photoelectric sensors for high precision. Subsequent equipment may include:

- Lamination Machines for applying the decorative film layer and the wear layer.

- Surface Treatment Equipment like embossing rollers to simulate natural wood grain textures, and UV Coating Lines to apply a protective, highly wear-resistant finish.

- A final Manipulator or stacking machine handles the finished planks for packaging.

Key Technologies Driving Performance

The advanced performance of WPC flooring is a direct result of the core technologies embedded within the production line:

- High-Precision Extrusion Control: Precise control over temperature, pressure, and screw speed within the extruder is paramount for achieving the optimal fusion and dispersion of the wood and plastic components. This prevents defects and ensures the material’s structural integrity.

- Multi-Layer Compositing: WPC flooring is a multi-layered product. The line must integrate lamination technology to perfectly bond the different layers (such as the WPC core, LVT/vinyl layer, print film, and wear layer) without bubbling or delamination, contributing to the product’s overall stability and waterproof nature.

- Automation and Integration: Modern WPC lines are characterized by a high degree of automation, minimizing human error and ensuring continuous, high-volume output. The seamless integration of each component—from the mixer to the cutter—is necessary for a streamlined, defect-free manufacturing flow.

The ability of the WPC Floor Production Line to handle complex material formulations and deliver a high-quality, finished product is what cements WPC’s position as a preferred alternative to traditional flooring materials.