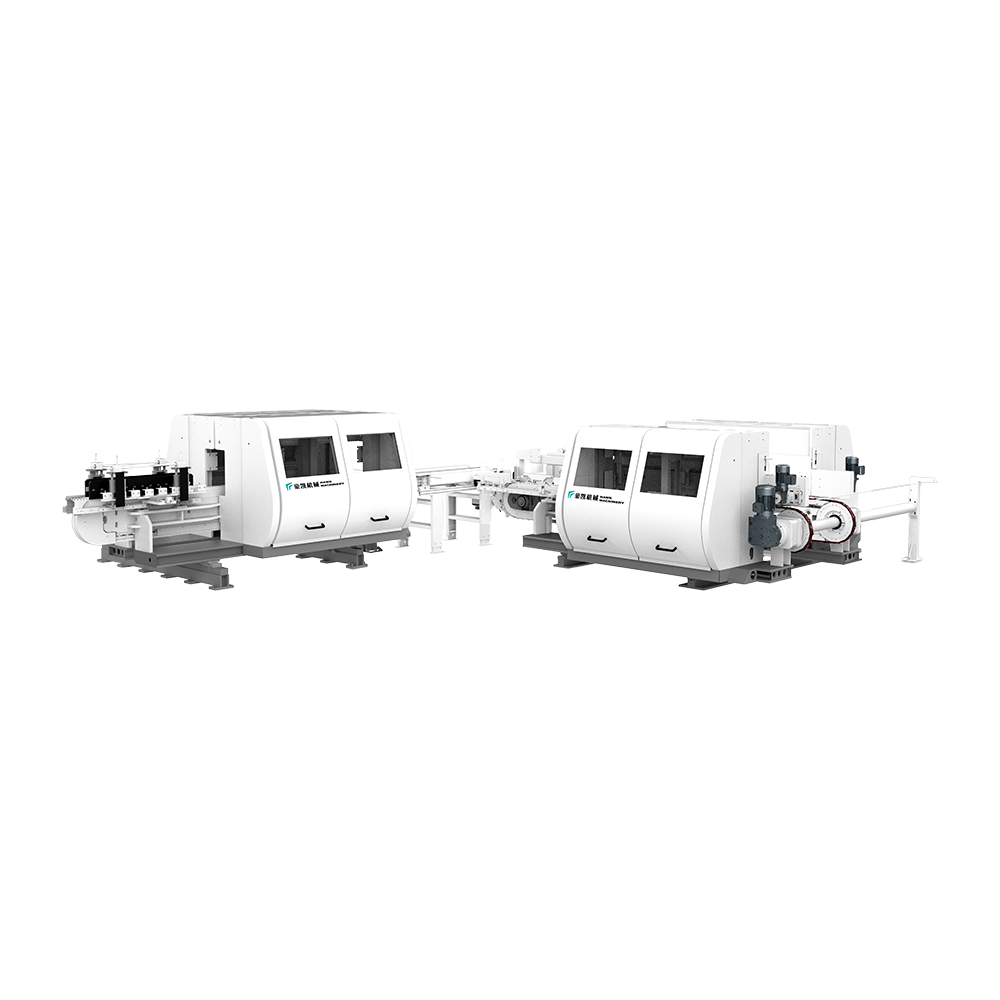

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsIf you’ve ever laid a new floor, whether it’s sleek laminate, classic hardwood, or modern vinyl, you know the single biggest headache isn’t the main installation—it’s the edges. The transition points where the floor meets the wall, a doorway, or a cabinet are where the quality of the job is truly judged. These areas require intricate cuts, curves, and angles to accommodate the less-than-perfect contours of a typical room. For professionals, achieving this level of flawless finishing quickly and efficiently has always been a challenge, requiring a mix of careful measurement, marking, and often tedious manual trimming.

This is where specialized tools like the VT Flooring Trimming Machine step in, transforming a frustrating, time-consuming process into a model of precision engineering.

At its core, the VT Flooring Trimming Machine is a highly specialized piece of equipment designed to accurately and rapidly shape the edges of flooring planks, particularly resilient and flexible materials like luxury vinyl tile (LVT) and vinyl composition tile (VCT).

Unlike a simple saw that cuts in a straight line, this machine is engineered to handle the complex, three-dimensional geometry required for professional flooring installation. Its genius lies in its ability to simultaneously address several common challenges:

The machine operates on a deceptively simple principle: secure the material, guide the cut, and finish the edge.

The flooring plank is placed onto a stable, vibration-dampening platform. The machine employs clamps or a vacuum system to hold the plank absolutely still. This is critical because even a tiny shift during the cutting process can ruin the alignment and create a visible gap once installed. This stability is the foundation of the machine’s precision.

The main action is performed by a specialized cutting head. Depending on the model and the material, this head might utilize:

The cutting action is carefully controlled to remove just the right amount of material—often down to a fraction of a millimeter. This level of control is what separates a custom-cut piece from one that looks like it was simply hacked off with a utility knife.

The VT Flooring Trimming Machine and similar technologies haven’t just made jobs easier; they’ve raised the standard of what customers expect from a flooring installation.

In the past, complex cuts near walls or heating vents could take ten minutes or more per piece, with a high likelihood of errors that resulted in scrapped material. By automating and standardizing this process, the machine drastically reduces installation time and minimizes the expensive waste from incorrectly cut pieces. This improves profit margins for contractors and speeds up project completion for clients.

Perhaps the most significant benefit is the improved look of the finished floor. The perfectly flush, gap-free installation achieved with these machines creates a luxurious, professional finish that is highly valued by architects, designers, and homeowners alike. The final touch—the perimeter of the room—is often the first thing people notice, and the machine ensures this detail is flawless.

In a world where DIY projects often fall short at the finishing touches, the VT Flooring Trimming Machine provides professional installers with a high-tech edge, ensuring that every floor they lay is a masterpiece of alignment and precision. It’s a testament to how specialized engineering can solve the seemingly small, yet critically important, problems of construction and design.