2021 China New Design Shrink Wrap - Hawk Machinery Automatic Grantry feeding system – Hawk

2021 China New Design Shrink Wrap - Hawk Machinery Automatic Grantry feeding system – Hawk Detail:

With the increase of production demand in many industries, the use of loading and unloading manipulator is more and more frequent, compared with the traditional manual operation, because of its three unique advantages, the automatic line production process is like a tiger with wings added, favored by the majority of customers.

First, save labor and improve efficiency

In the floor production workshop of mass processing, after using the loading and unloading manipulator to replace manual operation, the turnover area only needs 1-2 people to operate the machine, and the whole line body saves 8-12 people. The production line personnel allocation has been greatly optimized, and the production efficiency has been greatly improved. The first equipment investment, later can save a lot of labor costs. For the long-term production costs of customers, it is a very cost-effective configuration scheme.

Two, improve yield, reduce loss

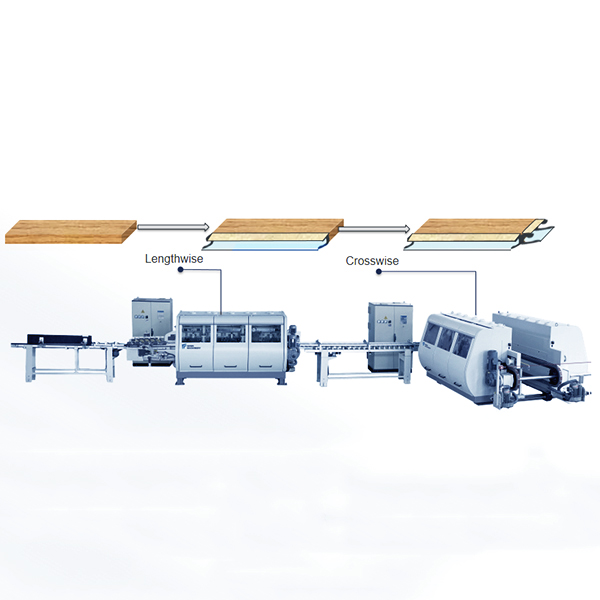

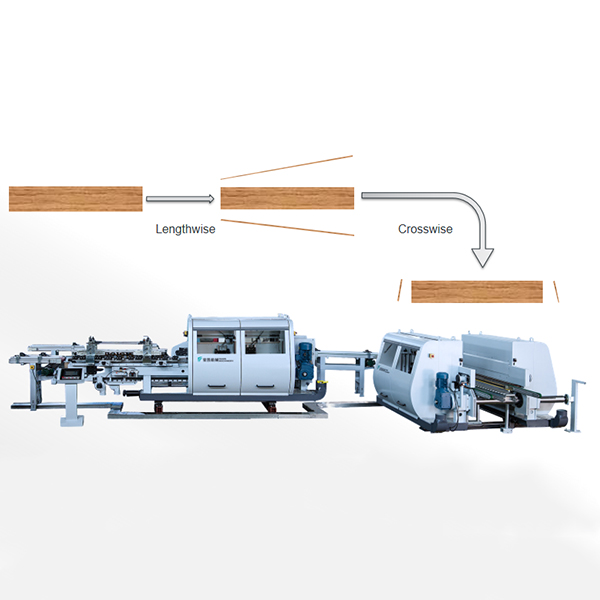

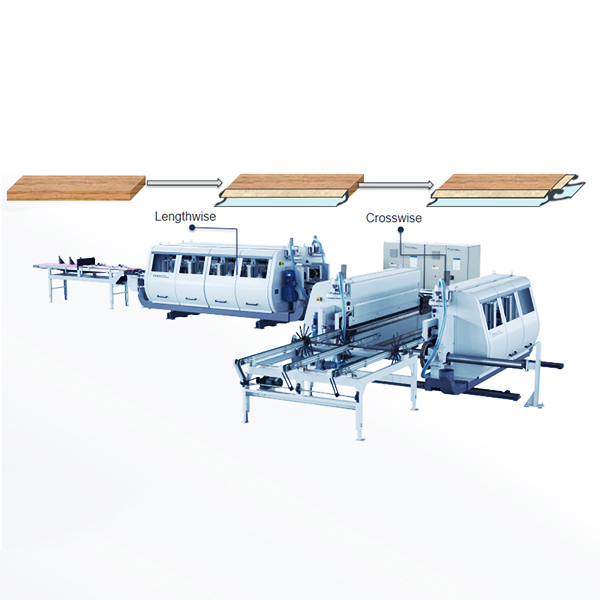

Robot automatic production line, from the feeding, sawing, grooving, blanking is completely completed by the machine, reduce the manual operation of the middle link, effectively avoid the workpiece due to manual loading and unloading of scratches and bruises, greatly improve product quality.

Three, fully intelligent operation

In order to comply with the requirements of the market, combined with the actual production and use of enterprises. The application of the loading and unloading manipulator is more intelligent. The manipulator is linked with the automatic line. When the automatic line is opened, the parameters of the manipulator are automatically adapted and adjusted, and the intelligent operation is synchronized. The machine is fully intelligent to liberate the staff hands heavy work, further reduce the enterprise staff turnover rate.

The Hawk Machinery Auto Feeding System is advanced in technology, safe and reliable, with high production efficiency, with automatic feeding and changing function. The whole suction cup has suction plate, which has low requirements on the board position, and is especially suitable for the board which is used for slitting and health after slitting; The servo motor is easy to understand, the linear track is guided, the reciprocating frequency of the shifting machine reaches 16/min, the operation is stable, the noise is low, the impact force is small, and the service life is long.

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of 2021 China New Design Shrink Wrap - Hawk Machinery Automatic Grantry feeding system – Hawk , The product will supply to all over the world, such as: Nepal, Morocco, Bulgaria, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.