China Manufacturer for Sheet Corrugating Machine - 4-door double-ended milling groove – Hawk

China Manufacturer for Sheet Corrugating Machine - 4-door double-ended milling groove – Hawk Detail:

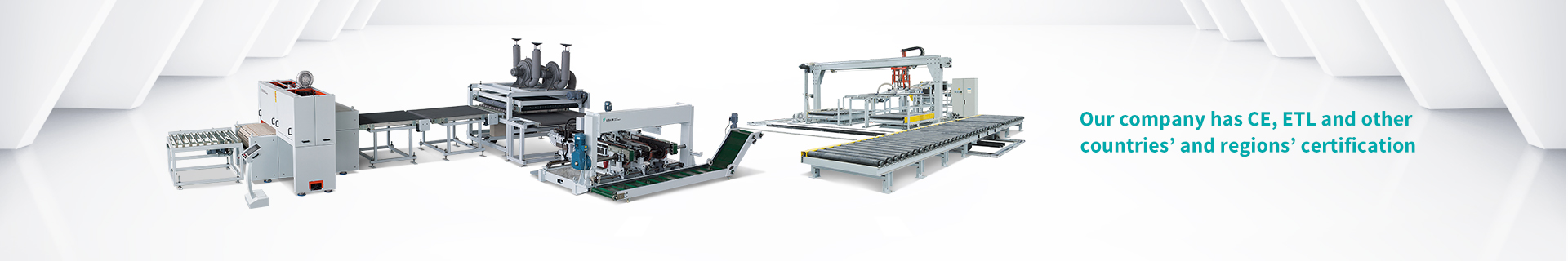

This equipment has a long body, high-speed design, and a separate compartment. It can be equipped with special equipment such as online painting and thermal transfer according to customers’ requirements. It is more stable for super long floor processing and improves machining accuracy.

| Model | Portrait HKS336 | Landscape HKH347 |

| The maximum number of axes that can be loaded | 6+6 | 7+7 |

| Feed rate (m/min) | 120 | 60 |

| Minimum workpiece width (mm) | 95 | – |

| Maximum workpiece width (mm) | 270 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1080 | 980 |

| Dimensions (mm) | 6200*2100*2000 | 5200*3800*1900 |

| Machine weight (mm) | 9 | 10 |

Product detail pictures:

Related Product Guide:

We keep on with the theory of "quality first, provider initially, constant improvement and innovation to meet the customers" with the management and "zero defect, zero complaints" as the standard objective. To great our company, we deliver the merchandise using the fantastic excellent at the reasonable price for China Manufacturer for Sheet Corrugating Machine - 4-door double-ended milling groove – Hawk , The product will supply to all over the world, such as: Istanbul, Liberia, Gabon, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

Write your message here and send it to us