High Quality for Roofing Sheets Machine - 3 Door High Speed Floor Slotting Machine – Hawk

High Quality for Roofing Sheets Machine - 3 Door High Speed Floor Slotting Machine – Hawk Detail:

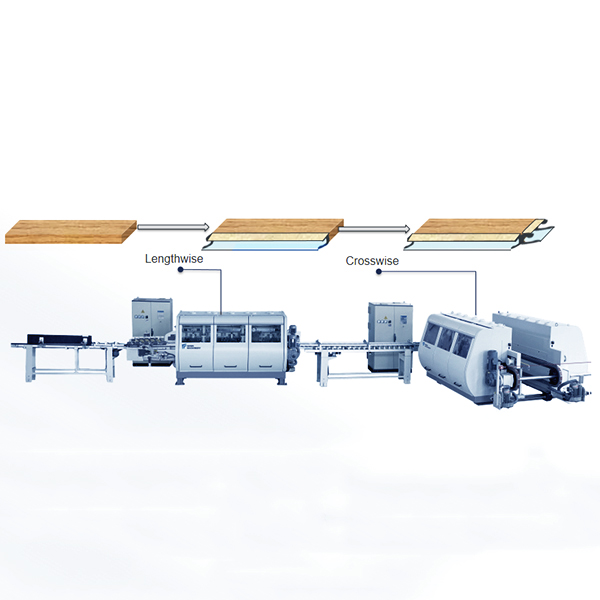

| Lengthwise | Crosswise | |

| Working Position | 6+6 | 6+6 |

| Speed(m/min) | 30-120 | 15-60 |

| Min.Width(mm) | 90 | – |

| Max.Width (mm) | 400 | – |

| Min.Length (mm) | 400 | 400 |

| Max.Length(mm) | – | 1600/2500 |

| Thickness (mm) | 4-25 | 4-25 |

| Cutter Dia (mm) | φ250-285 | φ250-285 |

| Working H (mm) | 1100 | 980 |

| Machine Size (mm) | 5200*3000*2000 | 5200*3800*1900 |

| Machine Weight (kgs) | 9500 | 9500 |

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line, using the latest international technology, after years of technical upgrading, with more than 600 customers at domestic and abroad use certification, suitable for PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, SMC plate and other types of plate slotting processing. Hawk Machinery 3 Door High Speed Floor Slotting Machine Line can let the plank do paint first, then do the slotting work and do not damage floor surface, can satisfy especially the floor processing production of all sorts of buckle type, have adaptability wide, adjust concise and fast, stability is good, the advantage of processing precision is higher.

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line, is the most classic configuration of our hawk machinery slotting line. The long side end and the short side end of the production line are equipped with 3 hatches, a total of 6 working positions for each side, the long side of the feeding bin can be extended, so that the longer plate feeding can be more stable. The transmission chain adopts double wide chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. In order to improve the accuracy of processing, in alignment with the position of the milling cutter using built-in pneumatic pressure plate device, the adjustment is simple and fast, and will not damage the surface of the floor, so that the floor assembly is more seamless.

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line with competitive price and high quality, high efficiency, good stability. Hawk Machinery 3 Door High Speed Floor Slotting Machine Line is the best choice for your processing OF PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, insulation board and other types of boards

Product detail pictures:

Related Product Guide:

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for High Quality for Roofing Sheets Machine - 3 Door High Speed Floor Slotting Machine – Hawk , The product will supply to all over the world, such as: Mongolia, El Salvador, Latvia, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.