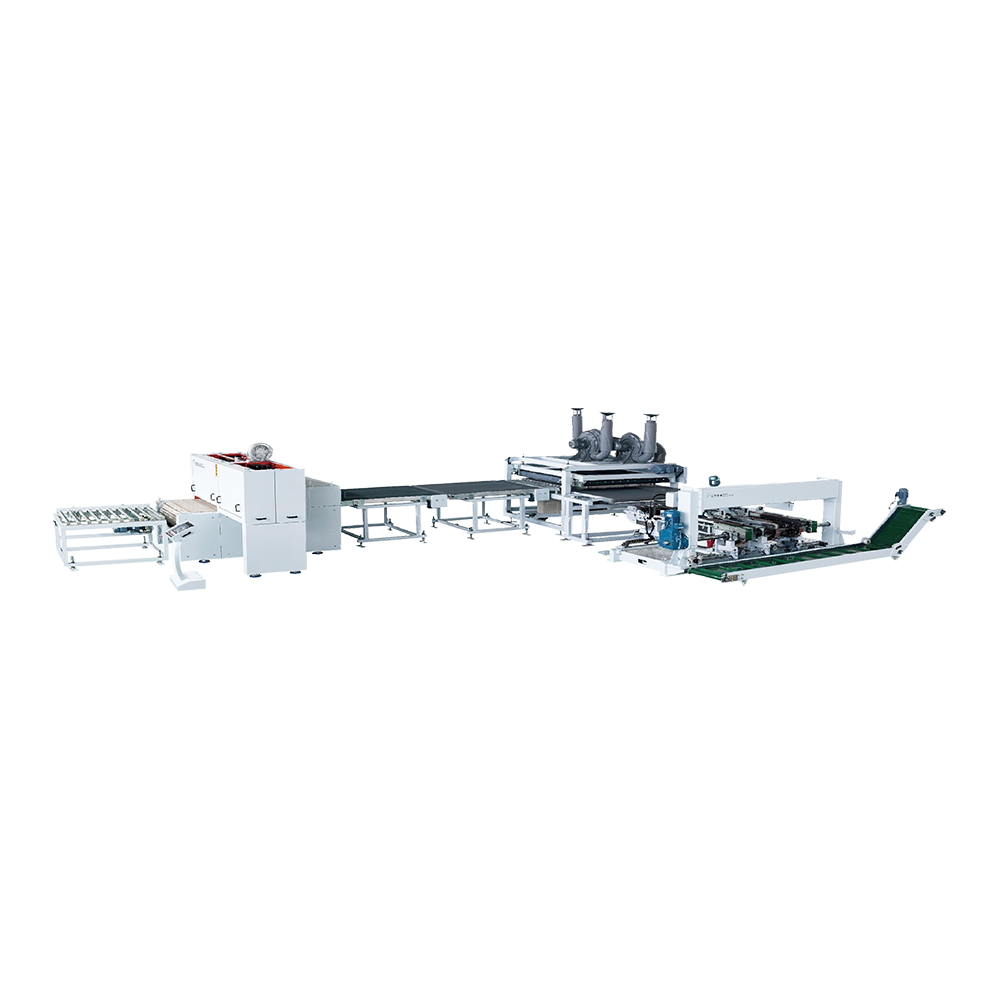

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsPolyvinyl Chloride (PVC) is a versatile, durable thermoplastic polymer used extensively across construction, plumbing, signage, and manufacturing. Its resistance to moisture, chemicals, and abrasion makes it a popular choice for pipes, fittings, window frames, and sheets. However, accurately and efficiently processing this material requires specialized equipment—the PVC cutting machine. Unlike general-purpose saws, these machines are engineered to handle the unique properties of PVC, such as its tendency to melt or chip under high friction and improper blade speed. Using the correct cutting machinery ensures smooth, clean edges, reduces material waste, and significantly increases production speed and quality.

The selection of a PVC cutting machine depends heavily on the form factor of the material being cut (pipes, profiles, or sheets) and the required precision and volume. Different cutting principles are employed to optimize the process for specific applications.

These are the most common type for cutting PVC pipe and window/door profiles. They utilize a spinning circular blade, often a carbide-tipped or HSS (High-Speed Steel) blade, with a specific tooth geometry designed to minimize heat generation. They are equipped with powerful clamping systems to hold the material securely and precise feed controls.

For cutting flat PVC sheets (like foam PVC or rigid PVC sheets used in signage and displays), CNC (Computer Numerical Control) machines offer unmatched versatility and precision. These machines can use either a rotating router bit or a tangential cutting knife.

Achieving a clean, burr-free cut in PVC requires attention to several technical details. The wrong parameters can lead to melting, burring, or chipping, which degrades the final product quality and can damage the machine.

The blade material and tooth configuration are critical. For PVC, it's generally recommended to use blades with a negative or low positive rake angle and a high number of small teeth. This configuration minimizes the 'grab' of the plastic, which can cause chipping, and helps dissipate heat effectively. Crucially, the peripheral speed of the blade (meters per minute) must be meticulously controlled. Too high a speed generates excessive heat and melts the PVC, while too low a speed can result in chipping or splintering.

PVC is relatively soft and flexible compared to metal. The clamping system on the machine must be robust enough to prevent vibration and movement during the cut without deforming the material. Pneumatic clamps are commonly used for automated systems. The feed rate—how quickly the material is pushed into the blade—is equally important. A smooth, constant, and relatively slow feed rate is typically preferred to ensure the blade has enough time to clear the plastic without causing friction-induced melting.

The following table summarizes the suitability of different cutting technologies for various PVC materials and applications.

| Machine Type | Best For | Key Advantage | Consideration |

| Circular Saw (Single/Double Head) | PVC Pipes and Window/Door Profiles | High speed and precision on straight and miter cuts; industrial capacity. | Limited to straight lines; requires fine-tuning of blade speed. |

| CNC Router | Thick PVC Sheets and Complex Shapes | Extreme versatility in 2D and 3D shapes; highly automated. | Slower processing time than circular saws; generates plastic dust. |

| Flatbed Digital Knife Cutter | Thin/Flexible PVC and Vinyl Films | Minimal material waste; very clean edges; no dust generation. | Not suitable for thick, rigid materials; limited to smaller production volumes. |

Safety protocols and regular maintenance are paramount for the longevity of the machine and the well-being of the operator. PVC dust can be a respiratory irritant, and the high-speed rotating blades present an obvious hazard.