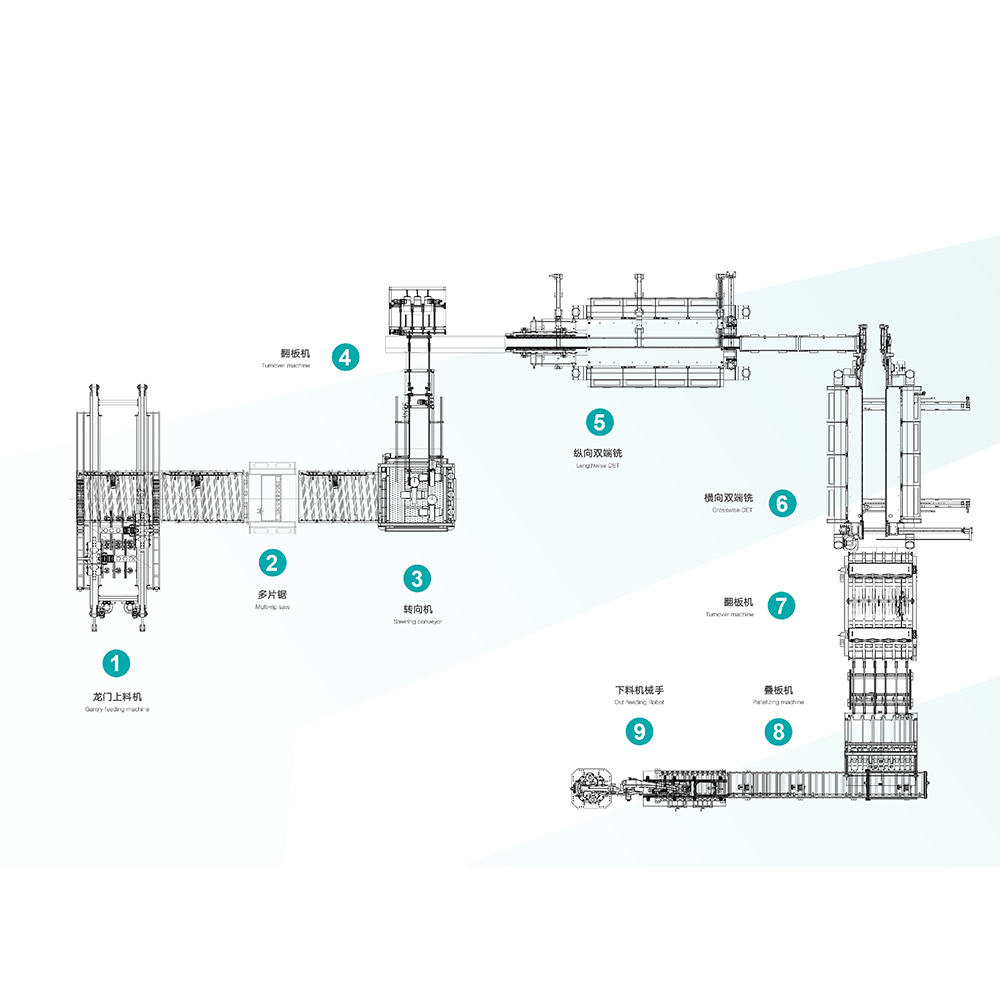

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsWPC stands for Wood-Plastic Composite. It’s a type of flooring that has revolutionized the industry by combining the best features of traditional wood and modern plastic materials. Unlike standard laminate or engineered wood, WPC flooring features a core layer made from a mixture of wood flour (or wood fibers), thermoplastic polymers (like PVC), and small amounts of additives.

This unique composition gives WPC floors several key advantages: they are 100% waterproof, exceptionally durable, and offer a comfortable feel underfoot. Initially designed for outdoor decking, WPC has been expertly adapted for indoor use, quickly becoming a favorite for kitchens, bathrooms, and basements.

The creation of a WPC floor is a fascinating industrial process, handled by a specialized system known as the WPC Floor Production Line. This line is a sequence of highly automated machinery that transforms raw materials into the finished, ready-to-install planks.

The process begins by precisely weighing and mixing the raw materials. This typically includes PVC resin powder, wood or calcium carbonate powder, and various additives like stabilizers and lubricants.

The materials are blended in a high-speed mixer. This critical step ensures a homogeneous compound, meaning all ingredients are evenly distributed, which is essential for the final product’s strength and consistency. The resulting material, often called a WPC compound or PVC compound, is now ready for the main manufacturing stage.

The heart of the WPC Floor Production Line is the extruder. The mixed compound is fed into this machine, where it’s melted under controlled heat and pressure.

Immediately after extrusion, the still-warm core board moves to the calendering section. This is where the floor’s visible layers are added and bonded to the core.

The combination of heat and pressure in the calender rollers permanently fuses all these layers together, creating a single, incredibly robust WPC sheet.

After lamination, the large WPC sheet must be properly cooled. This process, often called annealing, is crucial. It stabilizes the material’s internal structure and removes residual stress built up during the heating and pressing stages. This is a key factor in ensuring the planks remain dimensionally stable and don’t expand or contract significantly once installed in a home.

In the final stage, the large, cooled sheet is transformed into individual, ready-to-use planks.

A modern WPC Floor Production Line also contributes to sustainability. By utilizing wood-waste products (wood flour) and the long lifespan of the flooring, it reduces the need for virgin timber. Furthermore, the WPC planks are often recyclable at the end of their service life, creating a more circular manufacturing economy.