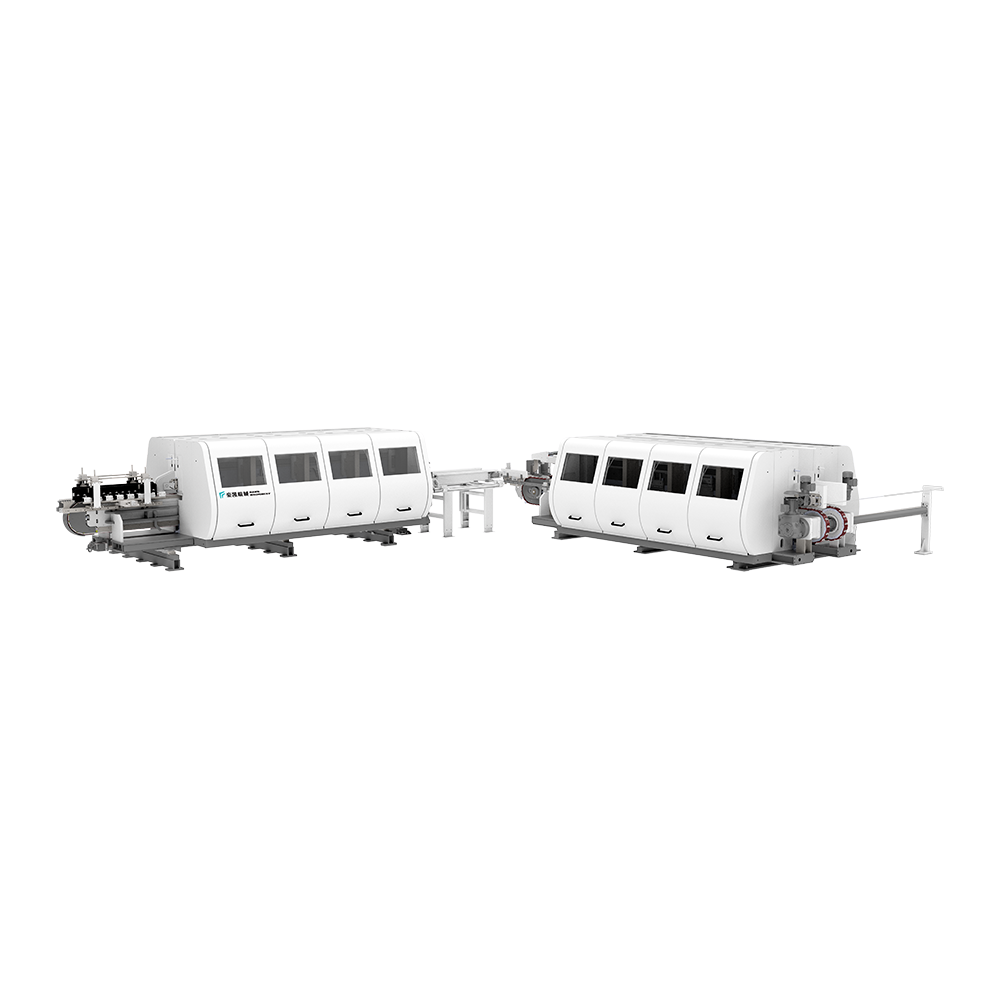

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsThe Double End Tenoner (DET) is a high-precision woodworking machine designed to process both ends of a workpiece simultaneously. This dual-sided capability ensures perfect parallelism and dimensional accuracy, which is nearly impossible to achieve with manual, single-sided processing. The machine typically consists of a fixed column and a movable column, allowing it to adjust to various workpiece lengths. Each side is equipped with multiple workstations, including sawing units, hogging heads, and milling or molding spindles. As the material is fed through the machine via a heavy-duty chain track system, these units perform complex profiling, grooving, or tenoning tasks in a single pass.

The heart of a Double End Tenoner lies in its feeding mechanism. Unlike standard machinery, a DET uses a synchronized double-chain drive with high-friction rubber pads. This system ensures that the workpiece remains perfectly perpendicular to the cutting tools throughout the entire feed cycle. Stability is further enhanced by top pressure beams—either belts or rollers—that clamp the material firmly against the chain. This prevents vibration and shifting, which is critical when working with large panels or delicate solid wood components where even a 0.1mm deviation can lead to assembly failure.

While traditionally used for furniture manufacturing, the versatility of the modern Double End Tenoner has expanded its utility across various sectors. Its ability to handle high-speed production makes it indispensable for facilities focusing on standardized components. By integrating CNC controls, modern DETs can switch between different profiles in minutes, making them suitable for both mass production and small-batch custom orders.

Selecting the right Double End Tenoner Machine requires an understanding of the machine's capacity and the complexity of the spindle configurations. High-end models often feature "jumping" units that can enter and exit the cut at specific points to prevent grain breakout on the trailing edge of the wood. The following table highlights the standard differences between light-duty and industrial-grade DET machines.

| Feature | Standard Series | High-Speed Industrial Series |

| Feeding Speed | 5 - 25 m/min | Up to 60+ m/min |

| Working Width | 200 - 2000 mm | 60 - 3000+ mm |

| Spindle Speed | 6000 RPM | 7200 - 9000 RPM |

| Control System | Manual/Digital Display | Full CNC / Touch Screen |

To maintain the tight tolerances required for tenoning, a strict maintenance schedule is essential. Because these machines generate a significant amount of dust and waste material, the extraction system must be powerful and clear of obstructions. Accumulation of debris in the chain track or on the spindle slides can lead to friction and heat, eventually causing misalignment. Operators should regularly check the lubrication levels of the chain tracks and the sharpness of the cutting tools to ensure clean, burr-free edges.