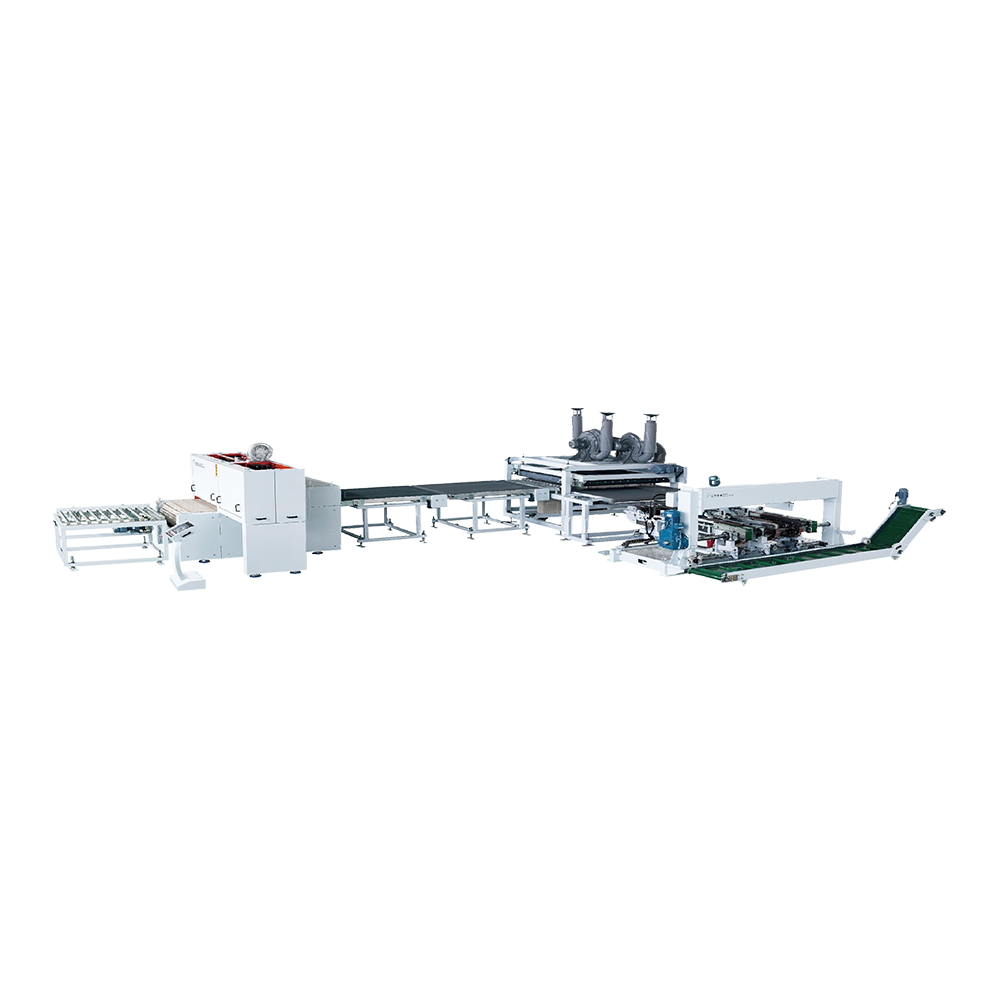

Floor slotting line (double end tenoner)

The product can slot the floor vertically and horizontally. The machine series c...

See DetailsWhen selecting a PVC cutting machine, the choice largely depends on the volume of work and the required precision of the finish. For high-capacity manufacturing, fully automatic orbital cutters are the industry standard, providing clean, burr-free edges without deforming the pipe. In contrast, workshop-based projects often utilize abrasive or cold saw machines that offer manual control for custom lengths. Understanding the mechanical differences between these machines is crucial for optimizing production speed and ensuring that the material integrity of the polyvinyl chloride is maintained during the thermal or mechanical stress of the cut.

Small-scale plumbing tasks or electrical conduit installations typically rely on handheld ratchet cutters. These tools use a sharpened steel blade and a mechanical advantage system to slice through the pipe. While they are highly portable, they are limited by the diameter of the pipe and can cause slight ovalization of the PVC if the blade is dull or the material is cold.

In extrusion lines, planetary saws move with the continuous pipe, rotating around its circumference to perform a square cut while the line is in motion. This ensures a seamless production flow and is often equipped with dust suction systems to manage the significant amount of debris generated during the process.

To help you determine which machinery suits your facility, the following table compares the most common configurations of PVC cutting equipment based on output and application.

| Machine Type | Cutting Range (Diameter) | Primary Advantage |

| Benchtop Chop Saw | 20mm - 110mm | High speed for bulk cuts |

| Orbital Pipe Cutter | 50mm - 315mm | Perfectly square, burr-free finish |

| Laser Cutting System | Custom/Thin-wall | Intricate shapes and profiles |

Maintaining a PVC cutting machine requires a dedicated schedule to prevent mechanical failure and ensure operator safety. Because PVC produces fine dust and potentially corrosive fumes if overheated, cleanliness is the most critical factor in machine maintenance. Regularly vacuuming the internal gears and blade housing prevents the buildup of "plastic flour" which can seize bearings or cause friction-related heat damage to the workpiece.

Operating a PVC cutting machine involves risks from both sharp moving parts and airborne particulates. Operators must be equipped with proper Personal Protective Equipment (PPE), including impact-resistant eye protection and respiratory masks. Modern industrial machines often feature safety interlocks that prevent the blade from spinning unless the safety guard is fully engaged and the workpiece is securely clamped. It is essential to never override these safety features, as the high RPM required for plastic cutting can lead to immediate injury if a material kickback occurs.

Furthermore, ensure that the workspace is well-ventilated. While PVC is stable at room temperature, the friction of a fast-moving blade can cause localized melting, releasing small amounts of hydrochloric acid vapor. Integrating an industrial extraction system at the point of the cut not only keeps the machine clean but also protects the long-term health of the workforce.