OEM manufacturer Ibr Roll Forming Machine - 3 Door High Speed Floor Slotting Machine – Hawk

OEM manufacturer Ibr Roll Forming Machine - 3 Door High Speed Floor Slotting Machine – Hawk Detail:

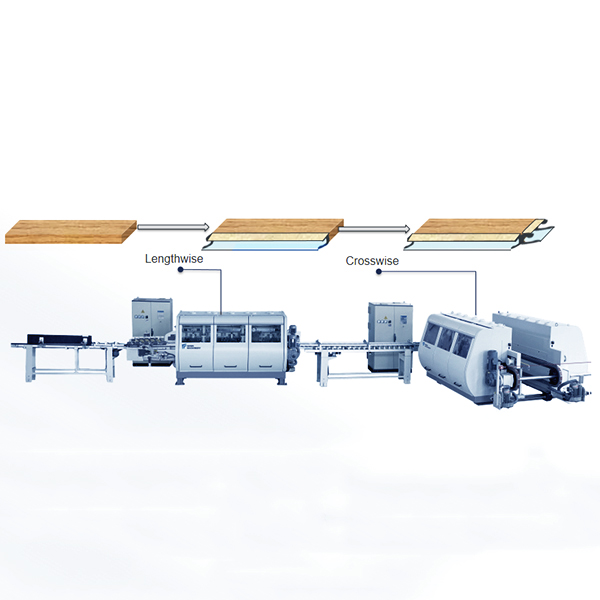

| Lengthwise | Crosswise | |

| Working Position | 6+6 | 6+6 |

| Speed(m/min) | 30-120 | 15-60 |

| Min.Width(mm) | 90 | – |

| Max.Width (mm) | 400 | – |

| Min.Length (mm) | 400 | 400 |

| Max.Length(mm) | – | 1600/2500 |

| Thickness (mm) | 4-25 | 4-25 |

| Cutter Dia (mm) | φ250-285 | φ250-285 |

| Working H (mm) | 1100 | 980 |

| Machine Size (mm) | 5200*3000*2000 | 5200*3800*1900 |

| Machine Weight (kgs) | 9500 | 9500 |

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line, using the latest international technology, after years of technical upgrading, with more than 600 customers at domestic and abroad use certification, suitable for PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, SMC plate and other types of plate slotting processing. Hawk Machinery 3 Door High Speed Floor Slotting Machine Line can let the plank do paint first, then do the slotting work and do not damage floor surface, can satisfy especially the floor processing production of all sorts of buckle type, have adaptability wide, adjust concise and fast, stability is good, the advantage of processing precision is higher.

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line, is the most classic configuration of our hawk machinery slotting line. The long side end and the short side end of the production line are equipped with 3 hatches, a total of 6 working positions for each side, the long side of the feeding bin can be extended, so that the longer plate feeding can be more stable. The transmission chain adopts double wide chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. In order to improve the accuracy of processing, in alignment with the position of the milling cutter using built-in pneumatic pressure plate device, the adjustment is simple and fast, and will not damage the surface of the floor, so that the floor assembly is more seamless.

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line with competitive price and high quality, high efficiency, good stability. Hawk Machinery 3 Door High Speed Floor Slotting Machine Line is the best choice for your processing OF PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, insulation board and other types of boards

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for OEM manufacturer Ibr Roll Forming Machine - 3 Door High Speed Floor Slotting Machine – Hawk , The product will supply to all over the world, such as: Estonia, Israel, New Delhi, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.