OEM/ODM Supplier Pneumatic Conveying Machine - 4-door double-ended milling groove – Hawk

OEM/ODM Supplier Pneumatic Conveying Machine - 4-door double-ended milling groove – Hawk Detail:

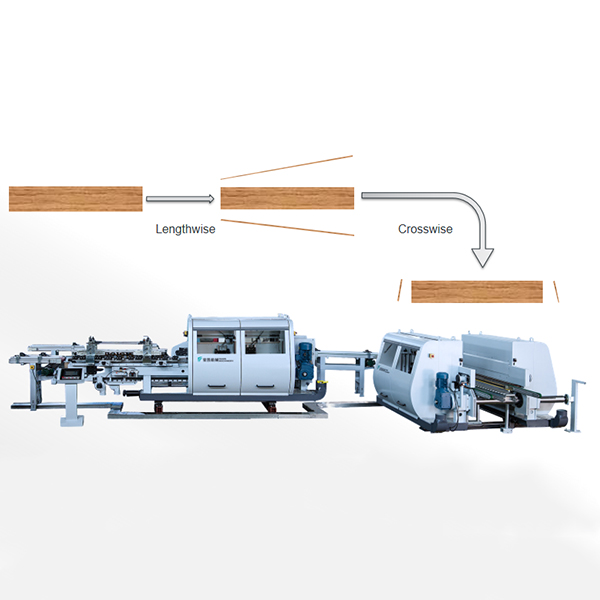

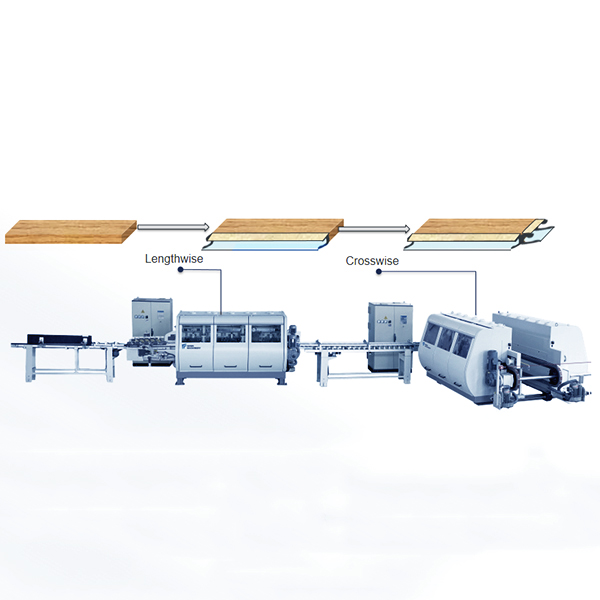

This equipment has a long body, high-speed design, and a separate compartment. It can be equipped with special equipment such as online painting and thermal transfer according to customers’ requirements. It is more stable for super long floor processing and improves machining accuracy.

| Model | Portrait HKS336 | Landscape HKH347 |

| The maximum number of axes that can be loaded | 6+6 | 7+7 |

| Feed rate (m/min) | 120 | 60 |

| Minimum workpiece width (mm) | 95 | – |

| Maximum workpiece width (mm) | 270 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1080 | 980 |

| Dimensions (mm) | 6200*2100*2000 | 5200*3800*1900 |

| Machine weight (mm) | 9 | 10 |

Product detail pictures:

Related Product Guide:

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for OEM/ODM Supplier Pneumatic Conveying Machine - 4-door double-ended milling groove – Hawk , The product will supply to all over the world, such as: Belgium, Qatar, Cairo, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

Write your message here and send it to us