Popular Design for Industrial Vacuum Scrubber - 4-door double-ended milling groove – Hawk

Popular Design for Industrial Vacuum Scrubber - 4-door double-ended milling groove – Hawk Detail:

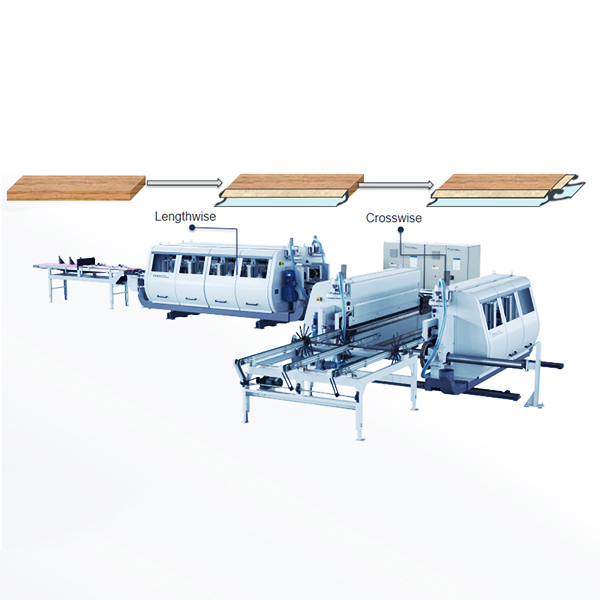

This equipment has a long body, high-speed design, and a separate compartment. It can be equipped with special equipment such as online painting and thermal transfer according to customers’ requirements. It is more stable for super long floor processing and improves machining accuracy.

| Model | Portrait HKS336 | Landscape HKH347 |

| The maximum number of axes that can be loaded | 6+6 | 7+7 |

| Feed rate (m/min) | 120 | 60 |

| Minimum workpiece width (mm) | 95 | – |

| Maximum workpiece width (mm) | 270 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1080 | 980 |

| Dimensions (mm) | 6200*2100*2000 | 5200*3800*1900 |

| Machine weight (mm) | 9 | 10 |

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Popular Design for Industrial Vacuum Scrubber - 4-door double-ended milling groove – Hawk , The product will supply to all over the world, such as: Houston, Eindhoven, Denver, We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Write your message here and send it to us