Renewable Design for Clip Lock Standing Seam Roll Forming Machine - 4-door double-ended milling groove – Hawk

Renewable Design for Clip Lock Standing Seam Roll Forming Machine - 4-door double-ended milling groove – Hawk Detail:

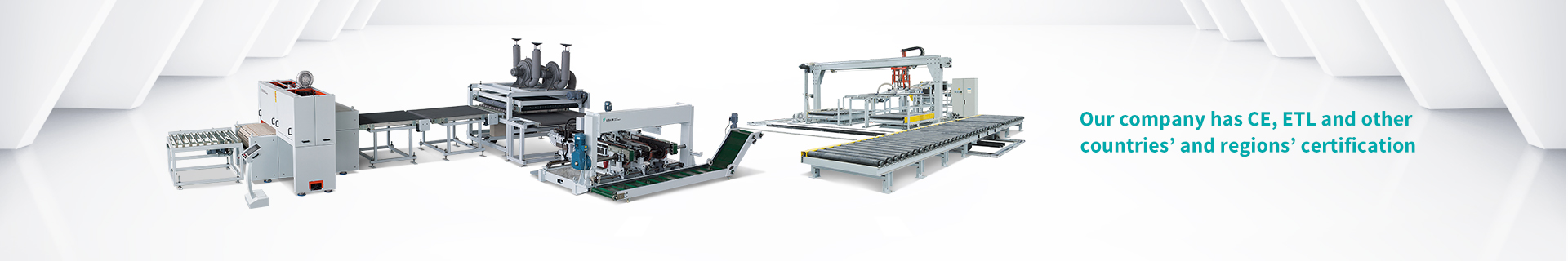

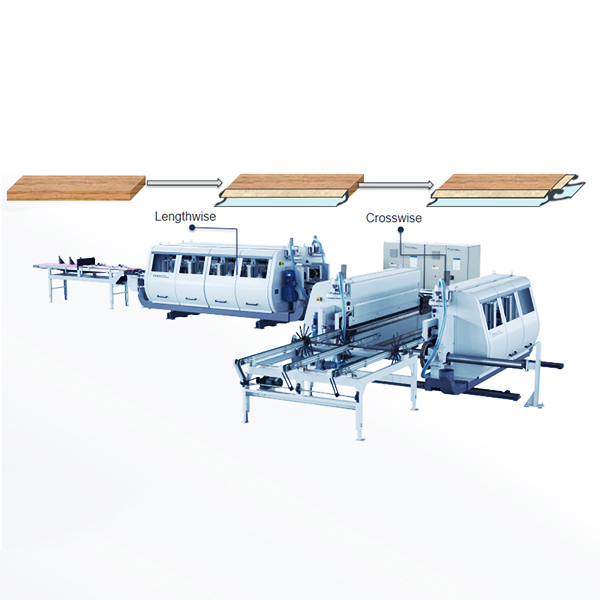

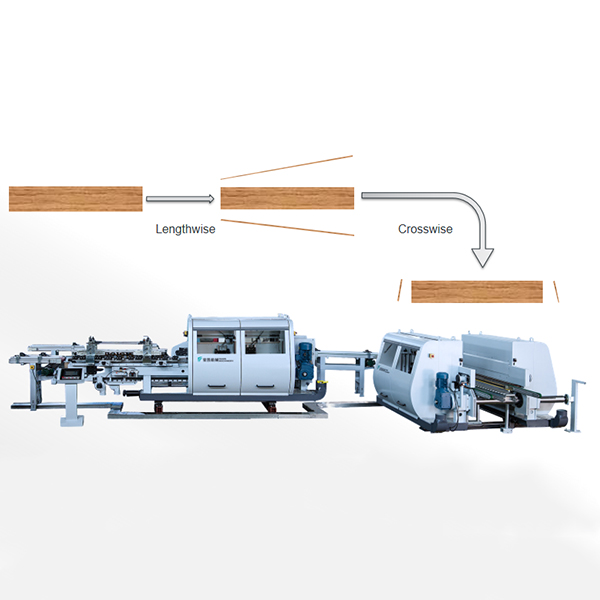

This equipment has a long body, high-speed design, and a separate compartment. It can be equipped with special equipment such as online painting and thermal transfer according to customers’ requirements. It is more stable for super long floor processing and improves machining accuracy.

| Model | Portrait HKS336 | Landscape HKH347 |

| The maximum number of axes that can be loaded | 6+6 | 7+7 |

| Feed rate (m/min) | 120 | 60 |

| Minimum workpiece width (mm) | 95 | – |

| Maximum workpiece width (mm) | 270 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1080 | 980 |

| Dimensions (mm) | 6200*2100*2000 | 5200*3800*1900 |

| Machine weight (mm) | 9 | 10 |

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for Renewable Design for Clip Lock Standing Seam Roll Forming Machine - 4-door double-ended milling groove – Hawk , The product will supply to all over the world, such as: Georgia, Dominica, Slovenia, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Write your message here and send it to us